This has nothing to do with a pony or Nebraska1.

In general there are two main types of fire issues: fires emanating from the interior of a building and fires emanating from the exterior of a building.

The single most important design considerations for fire safety relating to interior fires is discovery of the fire and getting out of the home quickly and safely. Smoke detectors, carbon monoxide detectors, and egress are central to this approach. This is a huge, huge, big deal. It is obvious…and we are not going to address it here.

The single most important design considerations for fire safety relating to exterior fires is the prevention of the spread of fire by vegetation to a building (“wildfires”) and the spread of fire from the exterior of one structure to another. Again this is a huge, huge, big deal…and obvious…and we are going to focus on it….particularly focusing on wildfires.

With respect to wildfires, the issue is burning embers. Roofs are particularly vulnerable to burning embers – both from the perspective of the roof covering and from the perspective of roof venting. If we could build roofs that are not vented in wildfire areas we would all be better off. We are going to cover this…but there are still places where we have to vent because we do not have a better way of dealing with the “confounding” issue even though we are in a wildfire risk area. More on that later.

We also have to deal with burning embers and walls…particularly walls with vented claddings. Again, more on that later. Seems to me that this venting thing can be a fire thing…yup…just ask the Brits (we were here before… BSI-098 Great Fire of London, August 2017).

Homes built in regions designated as Urban Wildland Interface Zones are at a high risk for fire exposure. Wildfires burn with speed and intensity that often leads to a high percentage of homes lost in these communities. However, the ignition of homes is typically not caused directly by flames but rather by ignited embers becoming airborne.

A bit of obvious things homeowners can address…particularly with respect to roof…and with respect to walls. For there to be a wildfire problem you need a fuel source. Some obvious fuel sources are within the control of homeowners… leaves, pine needles, ground debris, trash, grasses, and shrubs. Burning embers generated from these fuel sources are transported through the air and become deposited on roofs of homes or can be drawn into the attic through the openings in roof vents. Embers deposited on roofs may ignite debris on roof tops and in gutters such as leaves, pine needles and branches. Embers drawn through roof vents will ignite the combustible materials in the attic. Homeowners, clean your site, get rid of shrubs close to you building, don’t store trash beside your house, clean your gutters. Duh!

Let’s focus on design. Don’t vent your roof. Don’t vent your walls. Drain your roof. Drain your walls. This venting thing is such a big deal that venting, particularly roof venting, is often prohibited by local jurisdictions within Urban Wildland Interface Zones.

In terms of roof assemblies we should build them out of things that don’t burn. Roof assemblies are vulnerable to direct flames and should be constructed with roof coverings carrying “Class A” fire resistance or clad with metal roofing or tiles (we were here before… BSI-068 Rocks Don’t Burn, May 2013).

In terms of wall assemblies it is not uncommon in wildfire events that homes catch fire via the entry of airborne embers/cinders behind vented cladding assemblies. If you are going to vent your cladding make sure you have screens that prevent the entry of airborne embers/cinders. These screens also serve a second function – the control of entry of insects and pests into the drainage and ventilation gap. Here is a big thought, have your vent space as small as possible…keep the vent space ¾ inch or less to limit fire propagation.

Bigger is not better.

The main objective to limiting fire spread is to slow air (oxygen) from feeding a fire. Where gaps are ¾ inch or less the fire risk is minimal due to boundary layer friction of the two surfaces. Fire within cladding assemblies where air gaps are small is starved for oxygen. Synthetic stucco assemblies such as exterior insulated foam systems (EIFS) pose a small fire risk as there is no gap between the thin exterior lamina and the extruded polystyrene (EPS) to which the lamina is adhered/bonded to, even though EPS is combustible. Drainage is provided behind the EPS by the gap resulting from installing vertical beads of adhesive that attach the foam to the water control layer. This gap is approximately 1/8 inch. You can get drainage in gaps as small as 1/32 inch. The key is to make this gap continuous.

Robust wildfire resiliency involves minimizing or eliminating roof ventilation, minimizing drainage gaps and back ventilation of claddings and providing screens that resist airborne ember/cinder entry. Fire-resistant claddings should be used. Additionally, fire-resistant continuous exterior insulation should be used or alternatively the combustible continuous exterior insulation should be protected.

Right off the bat an ignition-resistant or non-combustible cladding should be coupled with a drainage gap and water control layer to control hydrostatic pressure.

The water control layer can take numerous forms. It can be a mechanically attached membrane, a fully adhered membrane, a fluid applied coating, a sheet good with an integral water control layer or rigid insulation with sealed joints.

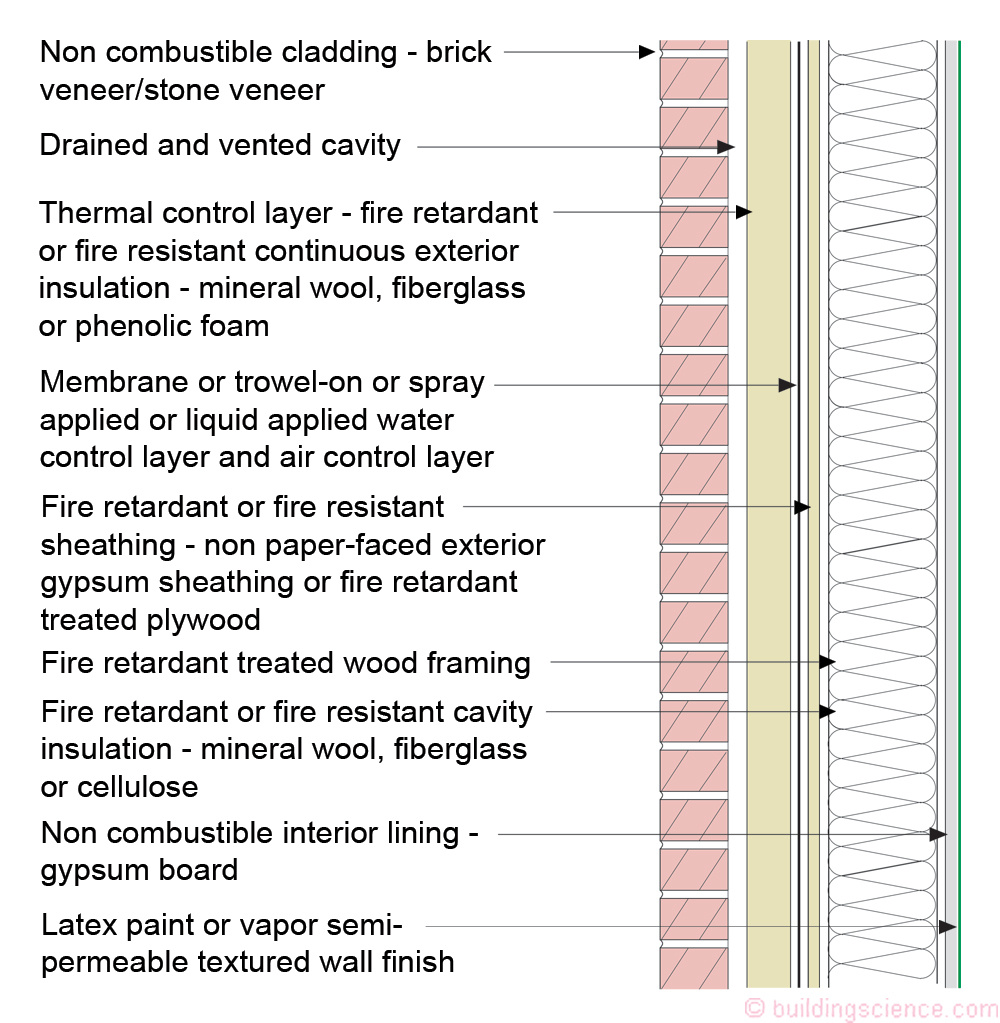

Figure 1 shows a wall assembly with an ignition-resistant or non-combustible cladding, fire retardant or fire resistant continuous exterior insulation, fire retardant or fire-resistant sheathing, fire retardant framing, fire retardant or fire resistant cavity insulation and a non-combustible interior lining such as 5/8 inch “Type X” gypsum board. The brick veneer/stone veneer is installed over a ¾ inch drained and vented cavity. This cavity should not be vented into soffit assemblies. It should be capped at the top and vented at the top to the exterior using weep openings similar to the weep openings typical at the bottom of the wall. It is important not to provide a pathway for airborne embers/cinders to enter soffit assemblies and ultimately roof assemblies. The 2021 International Wildland-Urban Interface Code (IWUIC) expressly prohibits soffit ventilation.

Figure 1: Wall assembly with a non-combustible cladding (brick veneer/stone veneer), fire retardant or fire resistant continuous exterior insulation, fire retardant or fire resistant sheathing, fire retardant framing, fire retardant or fire resistant cavity insulation and a non-combustible interior lining.

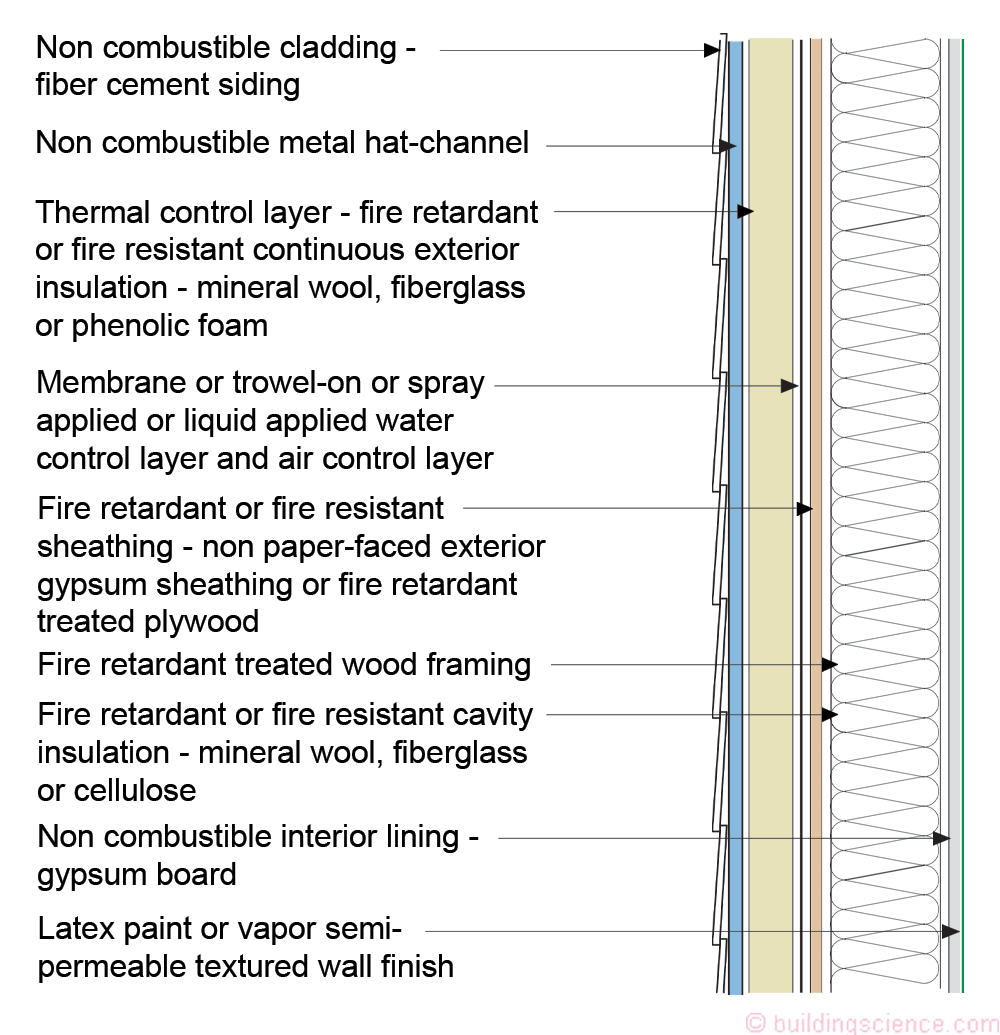

Figure 2 also shows a wall assembly with an ignition-resistant or non-combustible cladding, fire retardant or fire resistant continuous exterior insulation, fire retardant or fire resistant sheathing, fire retardant framing, fire retardant or fire resistant cavity insulation and a non-combustible interior lining. The fiber cement siding is installed over a 1/2 inch drained and vented cavity. This cavity should not be vented into soffit assemblies. It should be capped at the top. The air leakage typical for lap siding provides the necessary air change in the cavity to provide back cladding ventilation.

Figure 2: Wall assembly with a non-combustible cladding (fiber cement siding), fire retardant or fire resistant continuous exterior insulation, fire retardant or fire resistant sheathing, fire retardant framing, fire retardant or fire resistant cavity insulation and a non-combustible interior lining.

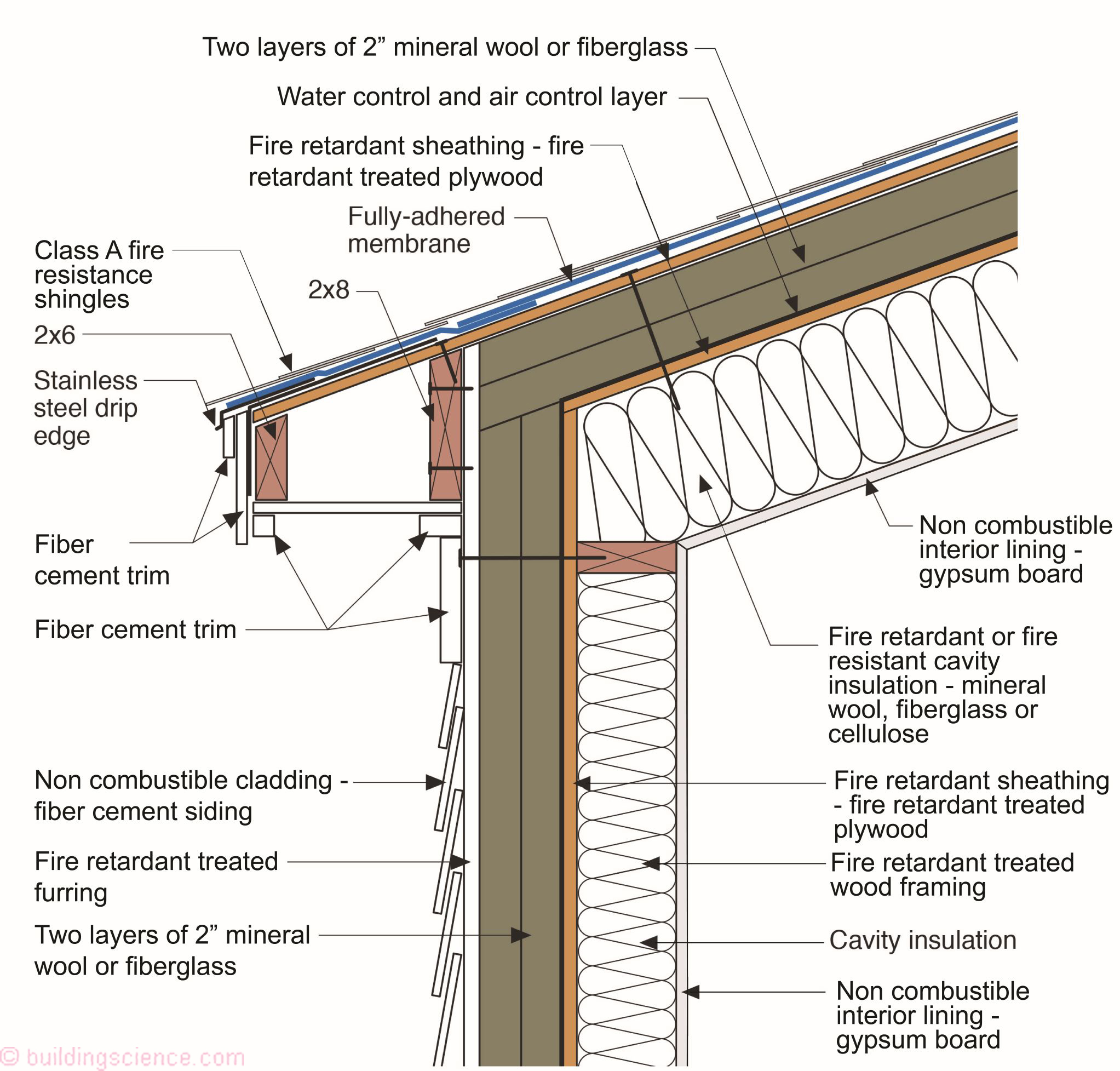

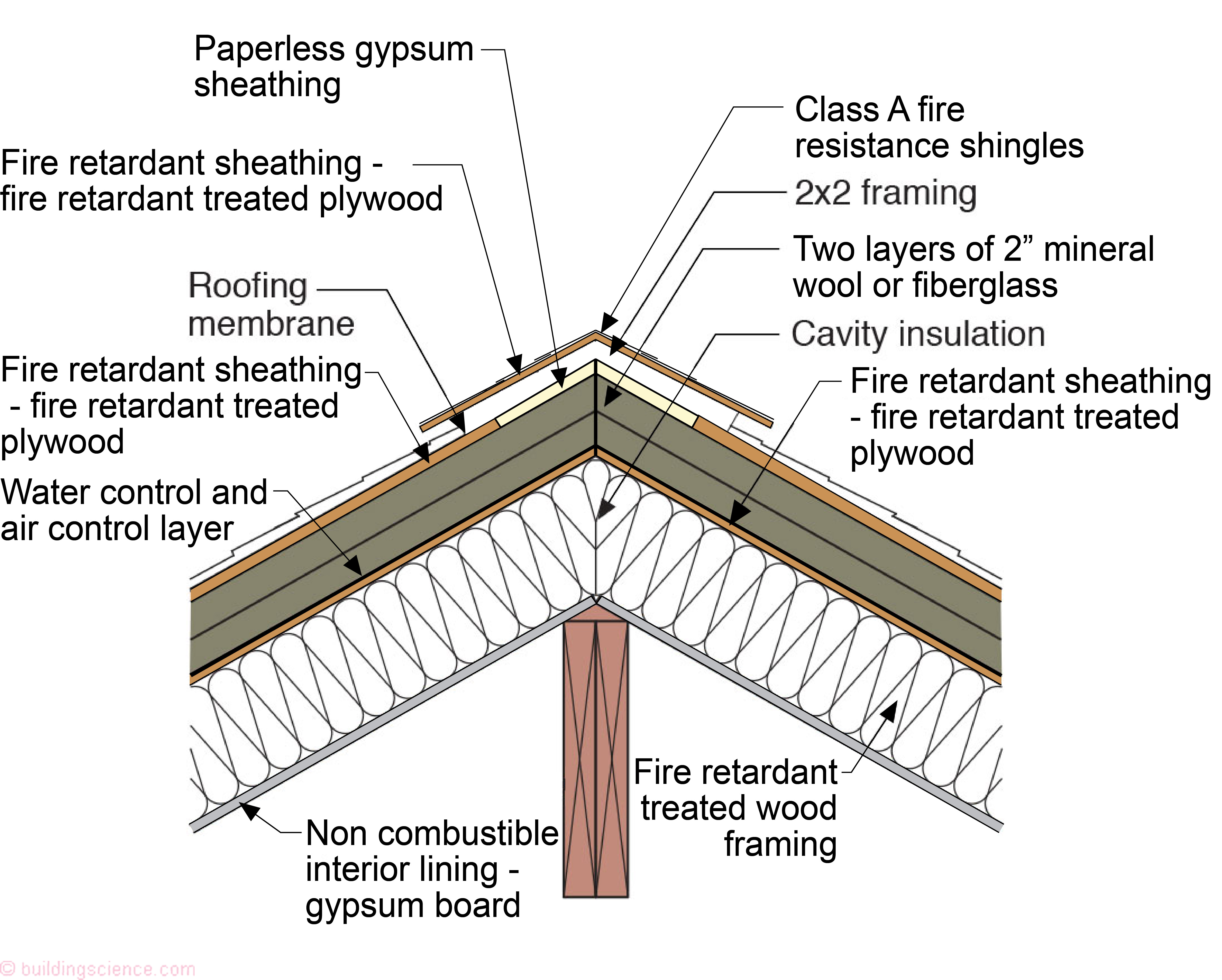

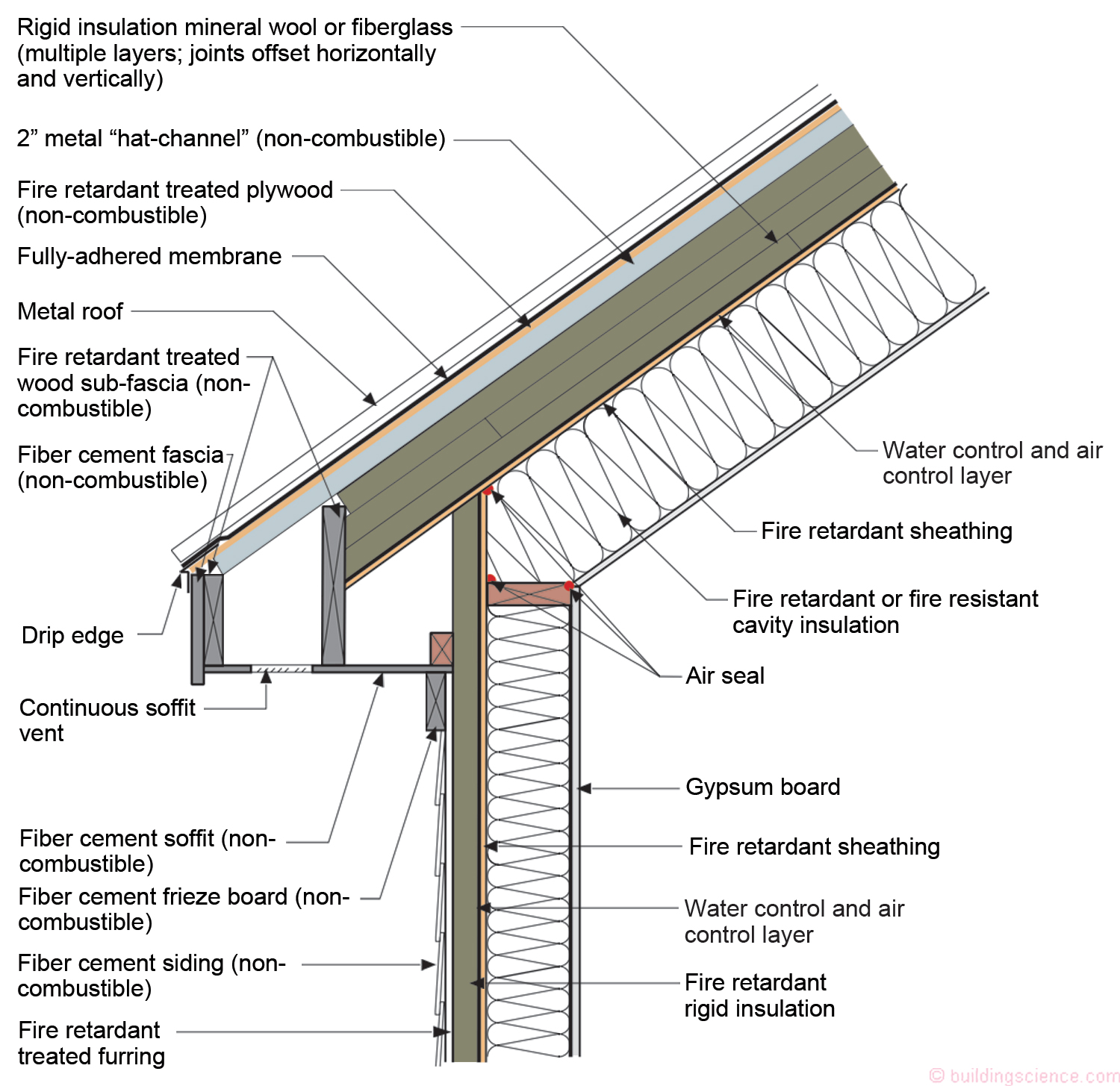

Figure 3 and Figure 4 show a building section connecting an unvented roof assembly constructed with fire resistant and fire retardant materials to a wall assembly with similar materials.

Figure 3: Building section connecting an unvented roof assembly constructed with fire resistant and fire retardant materials to a wall assembly with similar materials.

Figure 4: Building section showing a vapor diffusion ridge port constructed with fire resistant and fire retardant materials.

Now for the “confounding issue''. In places where it snows a lot we need attic ventilation to address ice damming. You can’t just do it with a highly insulated airtight unvented roof. The R-value of the snow cover will raise the snow-roof cladding interface surface temperature above the melt point of the snow even with a “super insulated” unvented roof. We have also covered this before (BSI-046 Dam Ice Dam, February 2011).

In a wildfire zone where it snows a lot if you don’t vent your roof you will get ice dams. The common technology used to control the inevitable ice dams are snow melt systems. Yech. Is there another option? But of course. Construct a vented roof out of non-combustible materials (and yes we were also here before…but I updated the information to cover what I think is a better way of doing things… BSI-068 Rocks Don’t Burn, May 2013).

In Figure 5 we use rigid mineral wool or fiberglass insulation (aka “fluffy rocks”), fire retardant treated plywood, fire retardant treated wood, metal roofing and fiber cement siding, trim and soffit material (rocks in sheet form). Steel “hat-channels” are installed over the top of this rigid board insulation. The “hat-channels” are screwed through the layers of insulation into the roof rafters. The “hat-channels” should be at least 2 inches thick to provide enough airflow to handle ice dams. Fire retardant treated plywood is screwed into the “hat-channels”. A fully adhered membrane and metal roof come next.

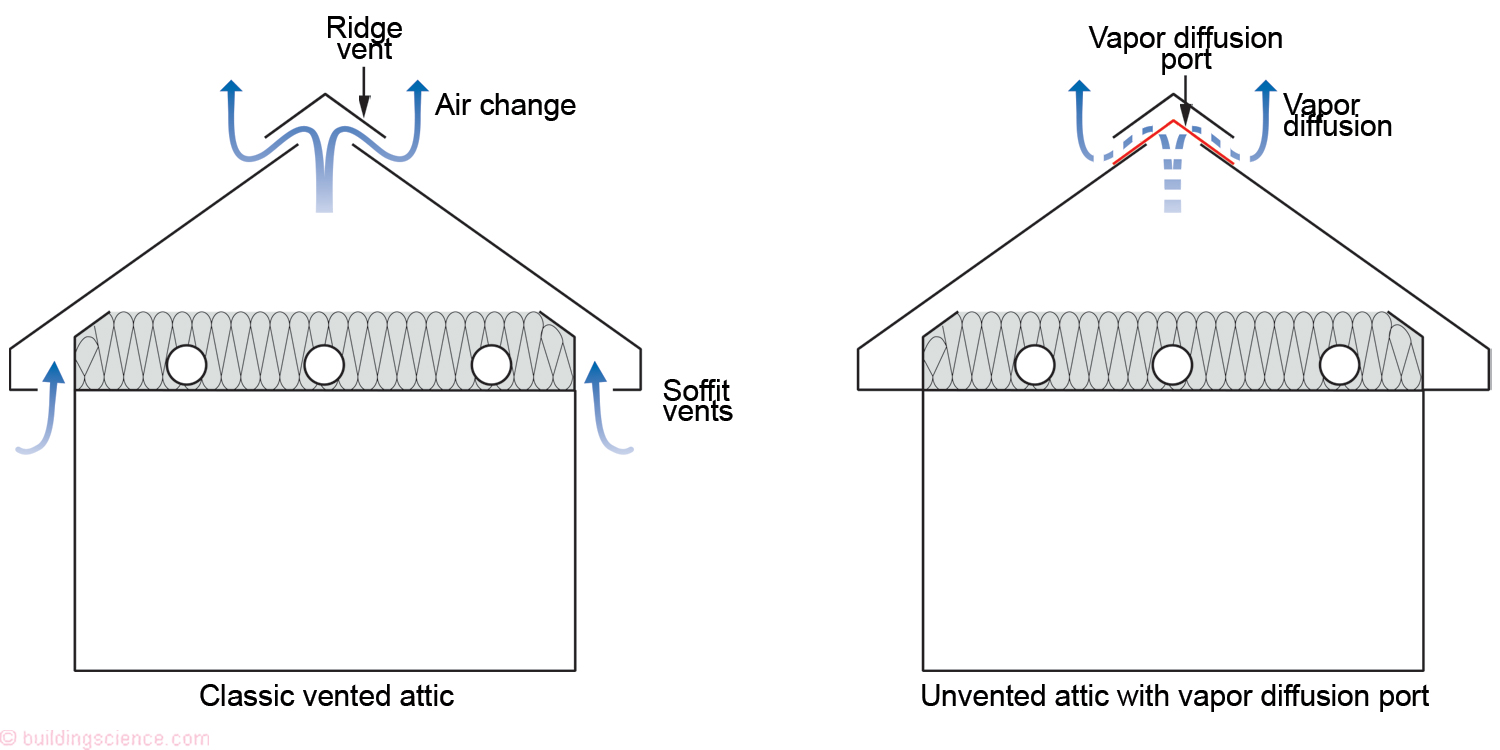

What if I do not want a cathedralized attic? Take a classic “vented” attic and convert it to an unvented attic with a vapor diffusion port (Figure 6). In the classic vented attic air change removes water vapor from the attic. In an unvented attic with a vapor diffusion port water vapor is removed via vapor diffusion rather than air change. And yes we were here before…twice…(Venting Vapor - ASHRAE Journal, August 2015 and No Sweat - ASHRAE Journal, April 2016. The key difference is that the vapor diffusion port covering must be non- combustible such as gypsum board (Photograph 1) or a non-combustible membrane (Photograph 2). Oh, by the way, the vapor diffusion port materials also need to be vapor open (20 perms or greater – wet cup method and the vapor diffusion port area needs to be 1:150 of the attic area.

Are we having fun yet? We need to pay the cost…to not have the loss. Apologies to James Brown.2

Figure 5: Vented Roof Constructed From Non-Combustible Materials - Use rockwool insulation (aka “fluffy rocks”), fire retardant treated plywood, fire retardant treated wood, metal roofing and fiber cement siding, trim and soffit material (rocks in sheet form) and follow the applicable physics and you get something that handles the embers and the ice dams. The metal “hat-channel” can be replaced with fire retardant treated wood 2x4’s lying “flat”. The structural geeks like the wood on the flat better. The fire geeks like the metal better. Note that the density of the rockwool will depend on the ground snow load for the location.

Figure 6: Vented vs Unvented Attic With Vapor Diffusion Port – In the classic vented attic air change removes water vapor from the attic. In an unvented attic with a vapor diffusion port water vapor is removed via vapor diffusion rather than air change.

Photograph 1: Vapor Diffusion Port – The vapor diffusion port covering must be non- combustible such as gypsum board.

Photograph 2: Vapor Diffusion Port – Non- combustible membrane covering for the vapor diffusion port. The vapor diffusion port materials also need to be vapor open (20 perms or greater – wet cup method and the vapor diffusion port area needs to be 1:150 of the attic area.

Footnotes

______________________________________________________________________________________________________________________

1 Michael Martin Murphy had a hit song in 1975 titled Wildfire about a pony named “Wildfire” lost in a blizzard in Nebraska….a favorite of David Letterman and Paul Shaffer for reasons that are “haunting and disturbingly mysterious”…much like the fire performance of walls and roofs during wildfire events…

2 I’ve Got Money – Song written and recorded by James Brown, 1962…”Havin’ fun, got money to burn…Cause I paid the cost to be the boss…”