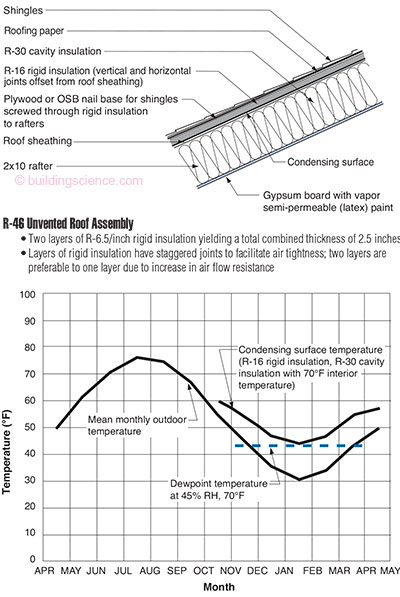

Unvented roof systems can be safely used in many different climates. In cold climates, insulating sheathing must be added exterior to the roof sheathing to prevent condensation on the underside of the roof sheathing.

Over the past five years several unvented roof insulation systems have been developed by the Building Science Consortium for use primarily in hot-dry and hot-humid climate zones. Designs and houses with unvented roof insulation systems have also been developed and constructed in cold and mixed climates.

The optimum systems developed to date are dependent on the climate location. The systems fall into two categories:

- systems where condensing surface temperatures are controlled

- systems where condensing surface temperatures are not controlled

The two categories essentially are the demarcation between regions where cold weather conditions occur with sufficient frequency and intensity that sufficient moisture accumulation from interior sources can occur on an uninsulated roof deck to risk mold, corrosion and decay problems.

The key is to keep the roof deck - the principle condensing surface in roof assemblies - sufficiently warm throughout the year. This can be accomplished either because of the local climate or as a result of design - principally through the use of rigid insulation installed above the roof deck. Where rigid insulation is installed above the roof deck, condensing surface temperatures are said to be controlled. Where the top of the roof deck is uninsulated, the condensing surface temperatures are said to be uncontrolled.

The demarcation is specified as a distinction between regions where the monthly average temperature remains above 45 degrees F throughout the year and where it drops below 45 degrees F during the year. The criteria was selected for three reasons.

First, by keeping the roof deck above 45 degrees F, condensation can be minimized or eliminated. Condensation will not occur unless the dew point temperature of the interior air exceeds 45 degrees F and this air contacts the roof deck. This interior dew point temperature is approximately equal to an interior conditioned space temperature of 70 degrees F at an interior relative humidity of 45 percent. These are interior moisture conditions that can easily be avoided with air change/ventilation or the avoidance of over humidification during the coldest month of the year in the climate regions specified.

Second, a monthly average temperature was selected, rather than a design heating temperature, as it is more representative of building enclosure performance. Short term, intermittent "spikes" in parameters/ environmental loads are of interest to structural engineers and in the sizing of equipment, but are not typically relevant to moisture induced deterioration. Wood based roof sheathing typical to residential construction has sufficient hygric buffer capacity to absorb, redistribute and re-release significant quantities of condensed moisture should intermittent condensation occur during cold nights when the sheathing temperature occasionally dips below 45 degrees F. The average monthly conditions more accurately reflect moisture content in wood based assemblies.

Third, this definition characterizes a region that is almost identical to the ASHRAE definition of hot-humid climates if a 20 inch annual precipitation criteria is also added. A powerful argument can be made for unvented roof construction in hot-humid climates in order to control interior moisture. This definition allows simple unvented roof design ("just don't install vents") in a previously recognizable climate zone (ASHRAE's hot-humid zone). Practicality is also enhanced. Average monthly temperatures are easy to obtain as are

annual precipitation values. ASHRAE defines hot-humid climates as having a 67 degree F or higher wet bulb temperature for 3,000 or more hours during the warmest six consecutive months; or, a 73 degree F or higher wet bulb temperature for 1,500 or more hours during the warmest six consecutive months is difficult to apply.

Figure 1 is a map outlining the demarcation between regions that require the control of condensing surface temperatures and regions that do not. Note that both Hot-Humid and Hot-Dry Climate Regions do not require the control of condensing surface temperatures. However, all other regions require some form of control.

Figure 1: Hygrothermal regions

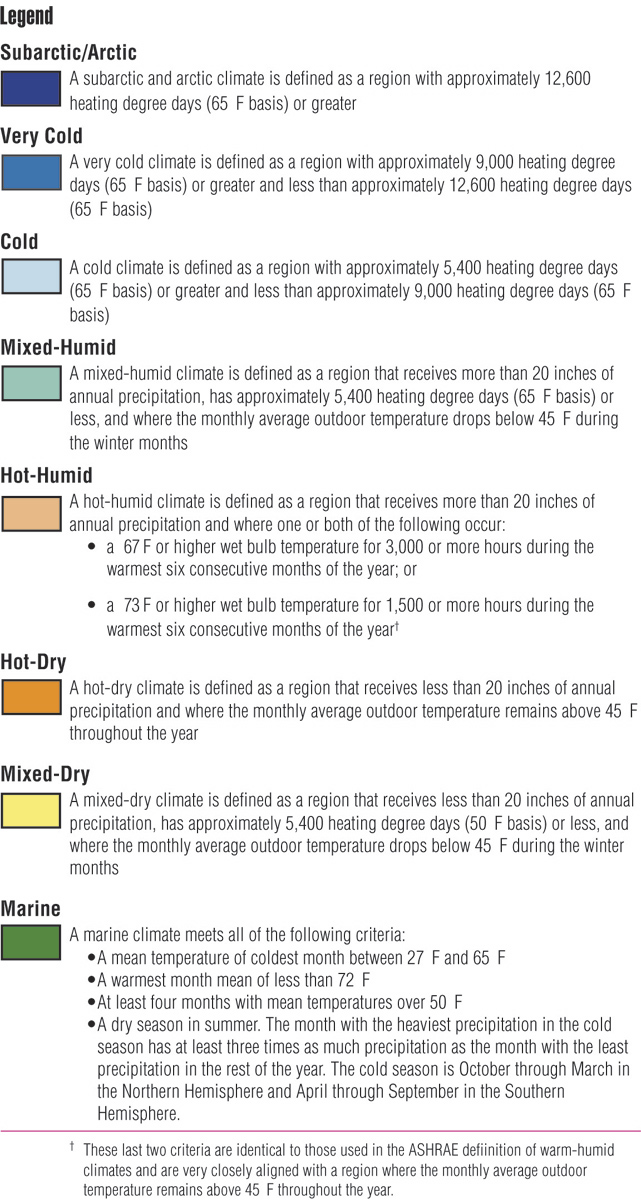

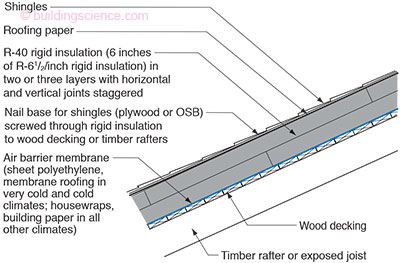

Control of condensing surface temperatures typically involves the installation of insulating sheathing above the roof deck. In residential wood frame construction this involves installing rigid insulation between the roof shingles and the roof plywood or OSB (Figure 2). The installation of the rigid insulation elevates the temperature of the roof deck to minimize condensation. Figure 3 and Figure 4 illustrate the differences between the two fundamental systems.

Figure 2: Rigid insulation used to control condensing surface temperatures—rigid insulation installed above roof deck; ratio of R-value between rigid insulation and batt insulation is climate dependent

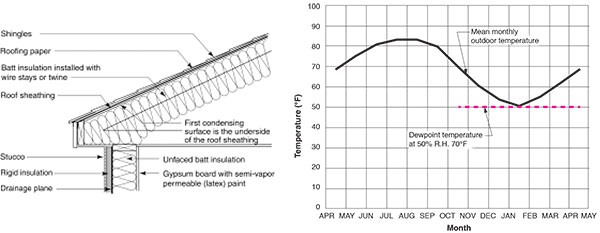

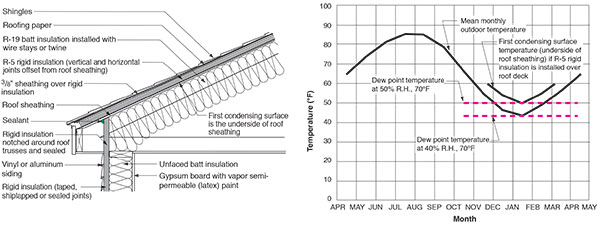

Figure 3 shows the potential for condensation of an unvented roof assembly in Houston, TX. Houston, TX is located in a Hot-Humid Climate Region. This roof assembly has no insulating sheathing installed above the roof deck. Figure 4 shows the potential for condensation of an unvented roof assembly in Dallas, TX. Dallas, TX is located in a Mixed-Humid Climate Region. Note that this roof assembly has rigid insulation installed above the roof deck in order to control the condensation potential.

Figure 3: Potential for condensation in Houston, Texas with unvented roof—there is no potential for condensation on the underside of the roof sheathing until interior moisture levels exceed 50% RH at 70°F

Figure 4: Potential for condensation in Dallas, Texas with unvented roof and insulating sheathing—there is no potential for condensation on the underside of the roof sheathing until moisture levels exceed 40% RH at 70°F; rigid insulation is recommended iin this roof assembly to raise the condensation potential above 50% RH at 70°F

The thermal resistance of the rigid insulation (thickness) necessary to control condensation depends on the severity of the climate. The colder the climate, the greater the resistance of the rigid insulation required. Note that the thermal resistance of the rigid insulation is based on the ratio of the thermal resistance of the insulation above the roof deck as compared to the thermal resistance of the insulation below the roof deck.

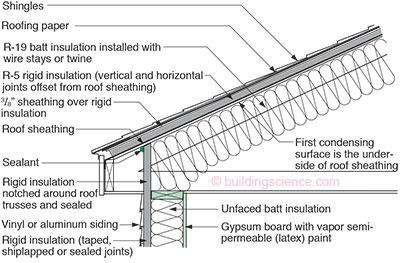

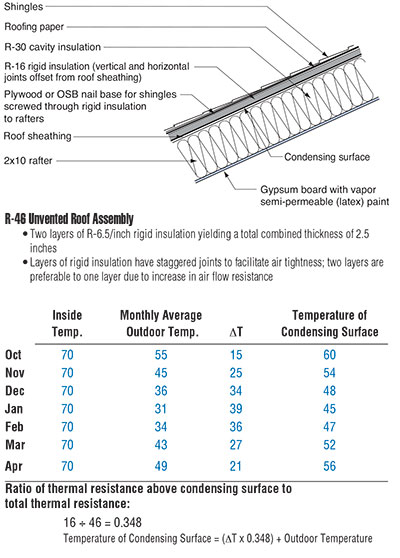

The key is to elevate the temperature of the condensing surface to 45 degrees F or higher during the coldest months of the year. Figure 5 shows the use of rigid insulation in a cathedral ceiling assembly in Washington, DC. A calculation procedure is presented that determines the temperature of the condensing surface. Figure 6 plots the temperature of the condensing surface. The graph shows that condensation within the roof assembly will not occur if interior conditions are maintained at 45 percent relative humidity or less at 70 degrees F during the coldest month of the year.

Figure 5: Condensing surface temperatures in Washington, D.C.—the greater the thermal resistance in the cavity, the lower the temperature of the condensing surface; the greater the thermal resistance of the rigid insulation, the higher the termperature of the condensing surface; in designs with no cavity insulation, only rigid insulation, yield the highest (warmest) condensing surface temperatures

Figure 6: Potential for condensation in Washington, D.C. with rigid insulation in unvented roof assembly—there is no potential for condensation until interior moisture levels exceed 45% RH at 70°F during the coldest month of the year if R-16 rigid insulation is installed oever a rafter cavity insulation to R-30

Figure 7 shows a roof design that is not as dependant on controlling interior moisture levels as the other roof designs presented. The absence of cavity insulation yields the highest condensing surface temperature of any of the designs presented. In this particular design, the condensing surface is the air barrier membrane installed over the wood decking. With this design interior relative humidities should be kept below 60 percent in order to control surface mold.

Figure 7: Compact unvented roof assembly—R-value increased to R-50 in severe-cold climate regions to control ice-damming; optimum roof assembly design to enclose pool areas and spas

In Cold and Very Cold Climate Regions where there is likely snow accumulation on roof surfaces, there is also the likelihood of ice-damming. In order to control ice-damming, heat flow from the interior to the roof cladding must be minimized. In Cold Climate Regions the minimum total R-value for the entire unvented roof assembly should be R-40. In Very Cold Climate Regions this minimum R-value should be increased to R-50. Note that in these types of unvented roof assemblies, interior vapor barriers are not recommended as these assemblies are expected to be able to "dry" towards the interior.

Also note that air sealing is critical in all unvented attic assemblies to prevent moisture problems associated with air leakage. Also, check out our "Vent on Venting".