“gas separation processes and open cell low density spray foam”1

Lots of attics insulated with open cell low density spray foam (Photograph 1, Photograph 2 and Photograph 3) are having problems – in hot humid climates, mixed humid climates, and cold climates. The problems are moisture related. The attics are “unvented” – open cell low density spray foam is installed directly on the underside of roof sheathing. The attics are humid. Very humid. Unacceptably humid. And the humidity collects at the upper portion of the attics.

Photograph 1: Florida Open Cell Low Density Spray Foam - The key to understanding what is going on is the storage capability of the wood based roof sheathing and the permeance of the spray foam. Open cell low density spray foam is very vapor open – around 30 perms per inch of thickness – and will allow moisture from the interior air to pass through it and migrate to the underside of the roof deck – the wood based roof sheathing.

Photograph 2: More Open Cell Low Density Spray Foam - Moisture in the indoor air migrates into the attic spaces, passes through the open cell low density spray foam and is stored in the wood based roof sheathing. It then gets driven out by temperature changes – largely driven by solar radiation – and accumulates at the upper portions of attics.

Photograph 3: Cold Climate Open Cell Low Density Spray Foam - “Leaky ductwork” did not solve the problem in cold climates with no attic ductwork. Only vapor retarder coatings coupled with some form of air change via a fan solved the problem in cold climates. The code requires a vapor retarder on open cell low density spray foam in IECC Climate Zones 5 and higher – but it is typically ignored by installers – and shame on them. And the manufacturers do not police the installers – and shame on them too. And the building officials that let them get away with it. Where is Aretha Franklin when you need her….”shame, shame, shame….”

For the record I do not have a problem with open cell low density spray foam. We have an engineering solution to the observed phenomenon that has been demonstrated to work. From my perspective the explanation is less important than solving the problem. You can use open cell low density foam in attics both north and south. But they have to be conditioned. Period. And in the north the open cell low density spray foam needs a vapor retarder. Note that we were here already: “Cool Hand Luke Meets Attics” ASHRAE Journal, April 2014. And I have a code change in the works.2 But the explanation is neat – and might even be true.3

So what is the problem? And what is the solution? And why now?

Problem first. Moisture in the indoor air migrates into the attic spaces, passes through the open cell low density spray foam and is stored in the wood sheathing. It then gets driven out by temperature changes – largely driven by solar radiation – and accumulates at the upper portions of attics.

Solution second. Removing the moisture in the air in the upper portions of attics by “conditioning” the attic with “dehumidified air” or removing the moisture in the air in the upper portions of attics by “air change”. See footnote on code change.

Why the problem now? Why did we not have this problem earlier? See “BSI-077: Cool Hand Luke Meets Attics” July 2015. Basically, leaky ductwork in unvented attics provided “conditioning”. Now that we have tighter ducts the conditioning does not happen. This “leaky ductwork” problem did not solve the problem in cold climates with no attic ductwork. Only vapor retarder coatings coupled with some form of air change via a fan solved the problem in cold climates. The code requires a vapor retarder on open cell low density spray foam in IECC Climate Zones 5 and higher – but it is typically ignored by installers – and shame on them. And the manufacturers do not police the installers – and shame on them too. And the building officials that let them get away with it. Where is Aretha Franklin when you need her….“shame, shame, shame….”

Now to the physics – actually, to the engineering…..

Air is a mechanical mixture of nitrogen, oxygen and water vapor. There are of course other things in the air – but we will conveniently ignore them in this discussion. Why does the water vapor – the moisture – end up at the tops of attics?

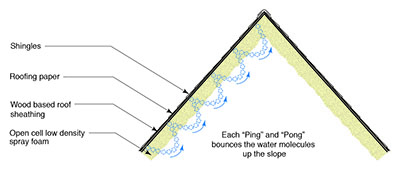

I have over the past several years referred to this as “ping pong” water (Figure 1) with the pings and the pongs bouncing upwards (Figure 2). Water passes through the open cell low density foam and is stored in the wood based roof sheathing. The water is then driven out – back into the attic space by solar radiation. Thermal and hygric buoyancy cause it to accumulate up top. Apparently this explanation has been unsatisfying – especially the hygric buoyancy part.

Figure 1: “Ping Pong” Water - I have over the past several years referred to this as “ping pong” water. Water passes through the open cell low density foam and is stored in the wood based roof sheathing. The water is then driven out – back into the attic space by solar radiation.

Figure 2: “Ping Pong” Water Bouncing Upwards - The pings and the pongs bounce upwards. Thermal and hygric buoyancy cause the water vapor to accumulate up top. Apparently this explanation has been unsatisfying – especially the hygric buoyancy part.

Even though moist air is less dense than dry air this density difference is not enough to cause the moisture to accumulate up top – according to the folks. Lots of folks, smart folks, friends of mine are having heartburn with all this. They say that air being warmer is the key not this pesky density difference.4 And besides the vapor pressures dominate. No vapor pressure difference can exist between the top of the attic space and the middle and the bottom. Check out the Second Law. Except that measurements show that it exists. I hate it when measurements and data interfere with theory.5

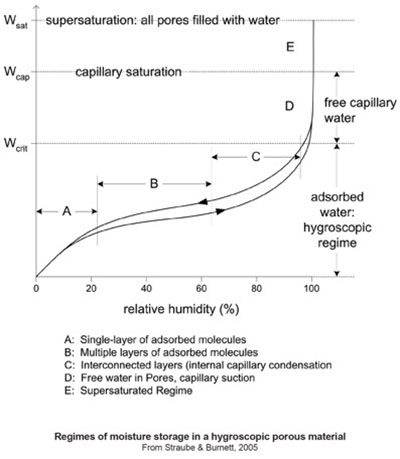

Not each ping is matched by a pong. The pings and pongs are different due to the difference in sorption and desorption rates in the roof sheathing. Hysteresis is a well known phenomenon with hygroscopic porous materials (Figure 3). But it gets more complicated still. Thank god for chemical engineers.

Figure 3: Sorption Curve - Not each ping is matched by a pong. The pings and pongs are different due to the difference in sorption and desorption rates in the roof sheathing. Hysteresis is a well know phenomenon with hygroscopic porous materials. Hat tip to John Straube and Eric Burnett for the curve. Great book.

Chemical engineers recognize what is going on immediately. To them this is an elegant gas separation process similar to pressure swing adsorption, but slightly more complicated. Pressure swing adsorption is an industrial gas separation process that takes advantage of an adsorbant’s ability to preferentially attract one gas molecule in a mixture. In the house, two forces create the separation – chemical potential (adsorption and capillary condensation) and gravity (density stratification).

Here is the way a chemical engineer looks at it:

1. Water is in the indoor air and I don’t care how it got there.

2. At night some of those water molecules are attracted through the foam and are adsorbed and absorbed in the wood sheathing (chemical potential)

3. When the sun comes up those same water molecules desorb and move back out of the foam (chemical potential).

4. When they exit the foam they are a little warmer than the attic air column and the surface of the foam has a higher molar concentration of water, so, they ride the buoyant film of gas skimming up along the surface of the foam – buoyant because it is both warmer and less dense (“hygric” buoyancy – see clouds).

5. Repeat night after night after night after night.

6. The sheathing (away from the ridge) never gets anywhere near its equilibrium moisture content, so, it can keep cycling endlessly (similar to pressure swing absorption).

7. Air exchanges between the space below the attic and the rest of the world, so, there is always a source of new water molecules to end up in this cycle that transports them up to the ridge.

We do not see these issues with closed cell high density spray foam as the closed cell high density spray foam decouples the wood based roof sheathing from the interior air. The key to this is the storage capability of the wood based roof sheathing. Open cell low density spray foam is very vapor open – around 30 perms per inch of thickness – and will allow moisture from the interior air to pass through it and migrate to the underside of the roof deck.

We also do not see these issues with open cell low density spray foam used in walls. In a typical house, the roof area is large with high exposure to solar gain and night sky radiation with minimal vapor control separation to the interior space. These are not major factors with walls (Photograph 4).

Photograph 4: Open Cell Low Density Spray Foam in Walls – We do not see these issues with open cell low density spray foam used in walls. In a typical house, the roof area is large with high exposure to solar gain and night sky radiation with minimal vapor control separation to the interior space. These are not major factors with walls and note that walls are typically covered with painted gypsum board – a pretty good vapor “throttle”.

Again, I repeat, it is ok to use open cell low density spray foam in conditioned attics….but the attics need to be conditioned. There has to be a moisture removal mechanism. I recommend air change. See my footnote about the code change.

References:

BA-1511: Field Testing of an Unvented Roof with Fibrous Insulation, Tiles, and Vapor Diffusion Venting http://buildingscience.com/documents/building-america-reports/ba-1511-field-testing-unvented-roof-fibrous-insulation-tiles-and

BA-1409: Field Testing Unvented Roofs with Asphalt Shingles in Cold and Hot-Humid Climates http://buildingscience.com/documents/building-america-reports/ba-1409-field-testing-unvented-roofs-asphalt-shingles-cold-and

Footnotes:

[1] I am indebted to Foster Lyons, chemical engineer turned builder extraordinaire and the bottle of Veuve Clicquot that lubricated the discussion that is the basis of this column. And also to Kohta Ueno the brains of our outfit – the keeper of the numbers and the only one with good enough eyesight to actually make out all those lines on a psychrometric chart…

[2] The following is up for consideration in Kansas City – despite the foam industry’s objections – why the foam industry is objecting to this is bizarre as it solves their problem in a low cost manner: 5.1.5. In climate zones 1, 2, and 3 air shall be supplied at a flow rate greater than or equal to 50 cfm per 1000 ft2 of ceiling. The air shall be supplied from ductwork providing supply air to the occupiable space when the conditioning system is operating. Alternatively one of the following shall occur:

1) air shall be supplied to the attic by a fan blowing air from the occupiable space into the attic.

2) transfer air from the occupiable space shall be provided by a fan exhausting attic air to the outside, or

3) mechanical dehumidification shall be provided to the unvented attic air space.

[3] Note that we have a problem and we have a solution to the problem. Don’t let the lack of consensus on the explanation to the problem interfere with fixing the problem. An engineer does not have to know why something works. The engineer just needs to know that it does work. The why is a “nice to have” but not a requirement. Think about friction. We still don’t understand it but we work with it every day. Thank god for coefficients.

[4] When you go to the psychrometic chart check out the air density lines. Notice that they are sloped. Moisture clearly has an effect on density. A 5 degree F dewpoint change is the density equivalent of a 1 to 2 degree F temperature change. Only evident to those with very good eyesight.

[5] Perhaps we should take a lesson from climate change and ignore the data when it conflicts with modeling and theory. Ah, I miss Yogi Berra…..“In theory there is no difference between theory and practice…but in practice there is…”