General Limit States Design, Hygrothermal Analysis

At a basic level a wall is an environmental separator. It keeps the outside out and the inside in. Easy to say, not always easy to do.

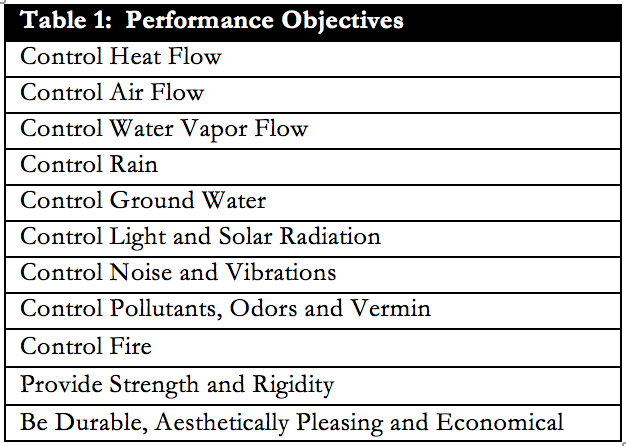

To function as an environmental separator it needs to meet specific “performance objectives”. The most elegant list of “performance objectives” comes from Hutcheon[1] and are found in Table 1.

A wall is never perfect. Sometimes the outside gets into the thing that separates the inside from the outside and you have to decide whether to kick it back or let it through. Sometimes the inside gets into the thing that separates the inside from the outside and you have to decide whether to kick it back or let it through. How much you kick back and let through depends on where you are, what is going on inside, what the assembly is made out of and how much energy is available.

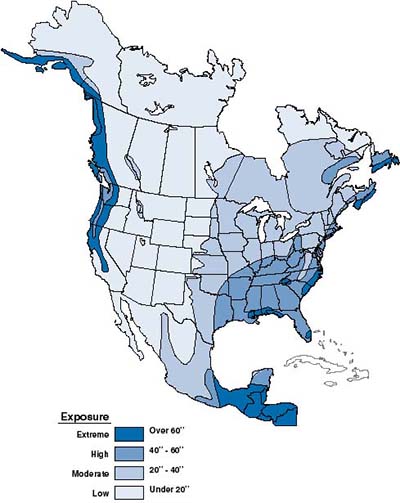

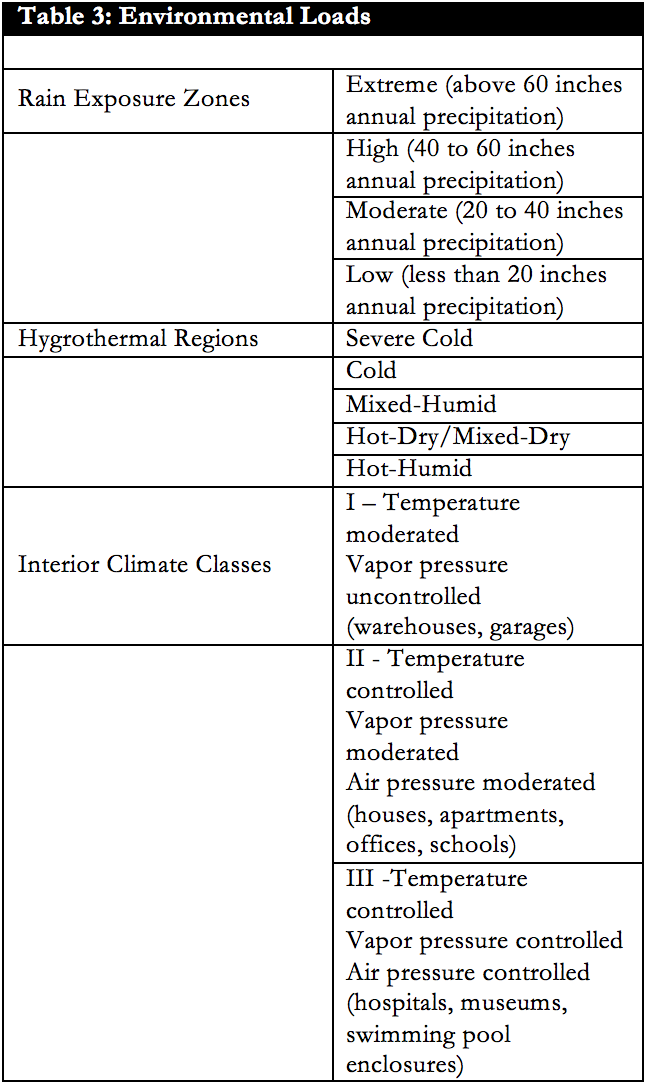

Where you are establishes the external environmental load. It rains more in Seattle than in Las Vegas. You probably need more rain control in Seattle than in Las Vegas. The rain exposure is an external environmental load (Figure 1).

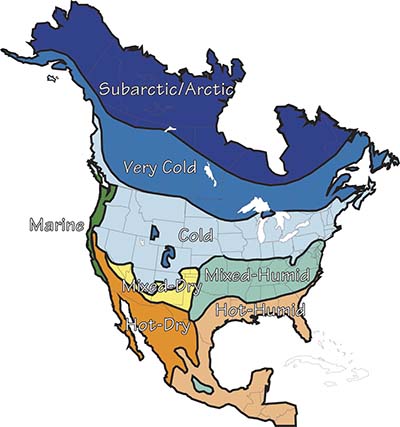

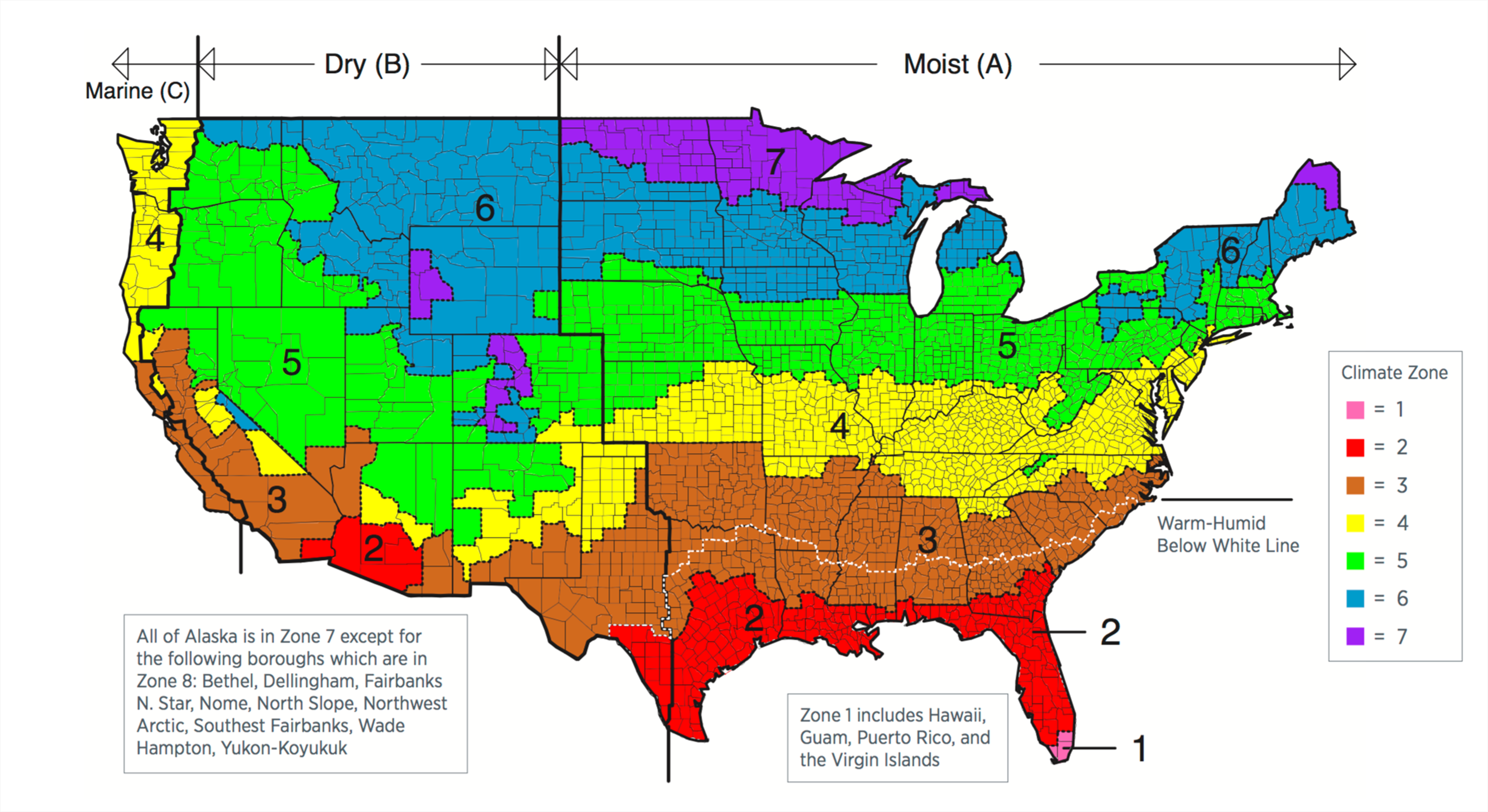

There is more. It is hot and humid in Miami. It is cold and dry in Edmonton. Walls in Miami look different than walls in Edmonton. The temperature and humidity outside is an external environmental load. They are referred to as “hygrothermal loads”. Figure 2 is a map of “hygrothermal regions”. If Figure 2 looks somewhat familiar, it should, it is based on the Koppen climate classification system (Figure 3). The model building codes “Climate Classes” are derived from Figure 2[2] (Figure 4).

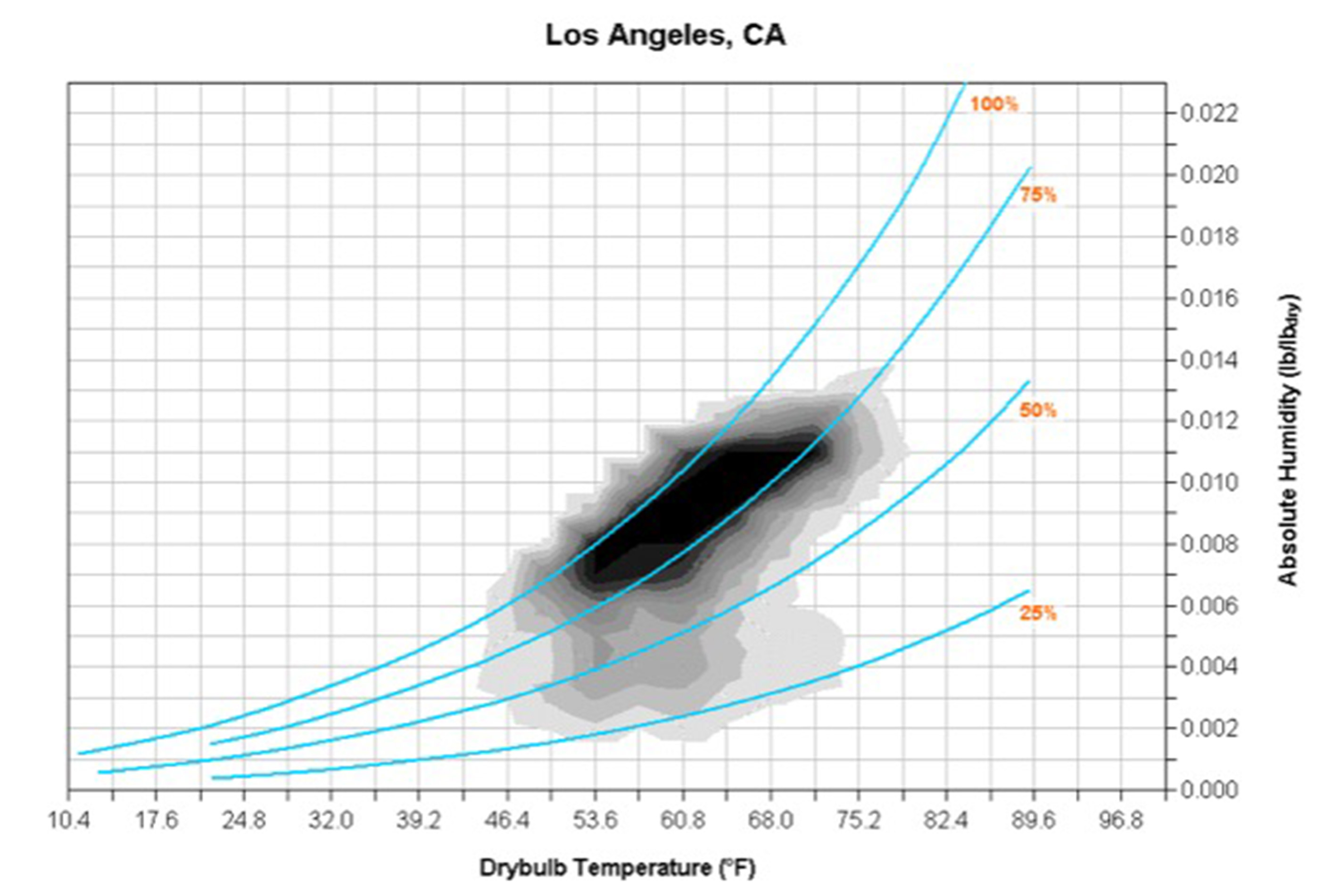

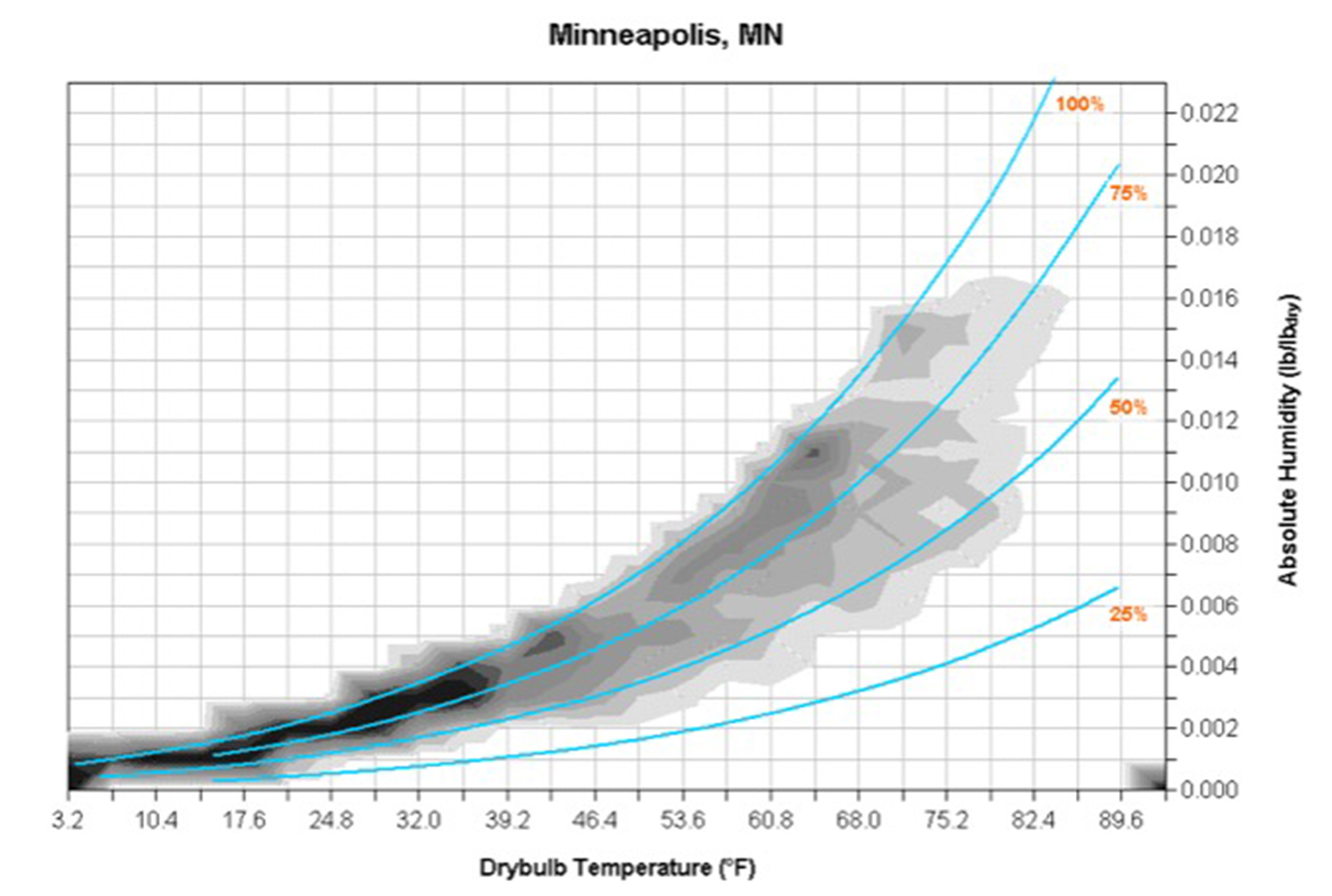

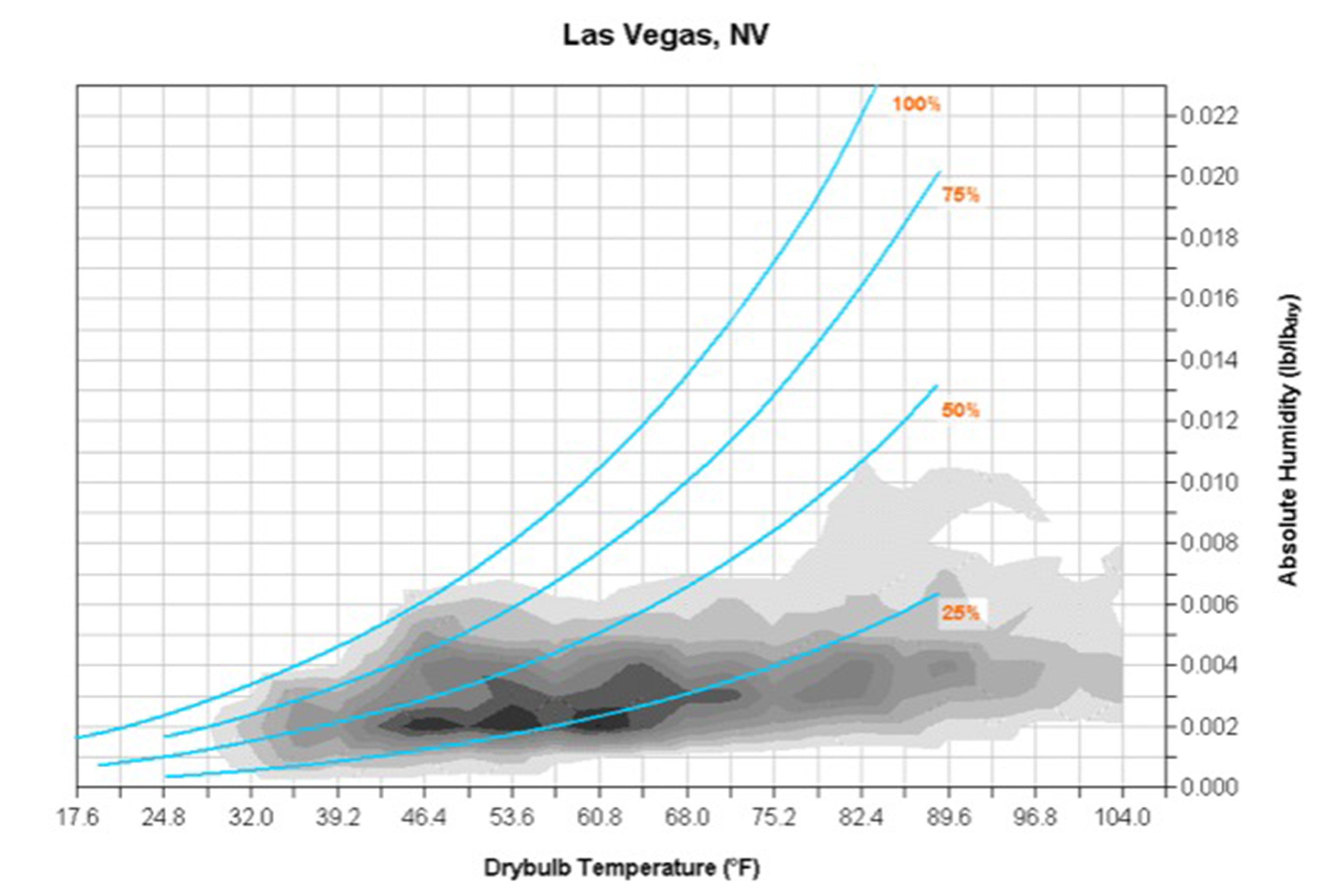

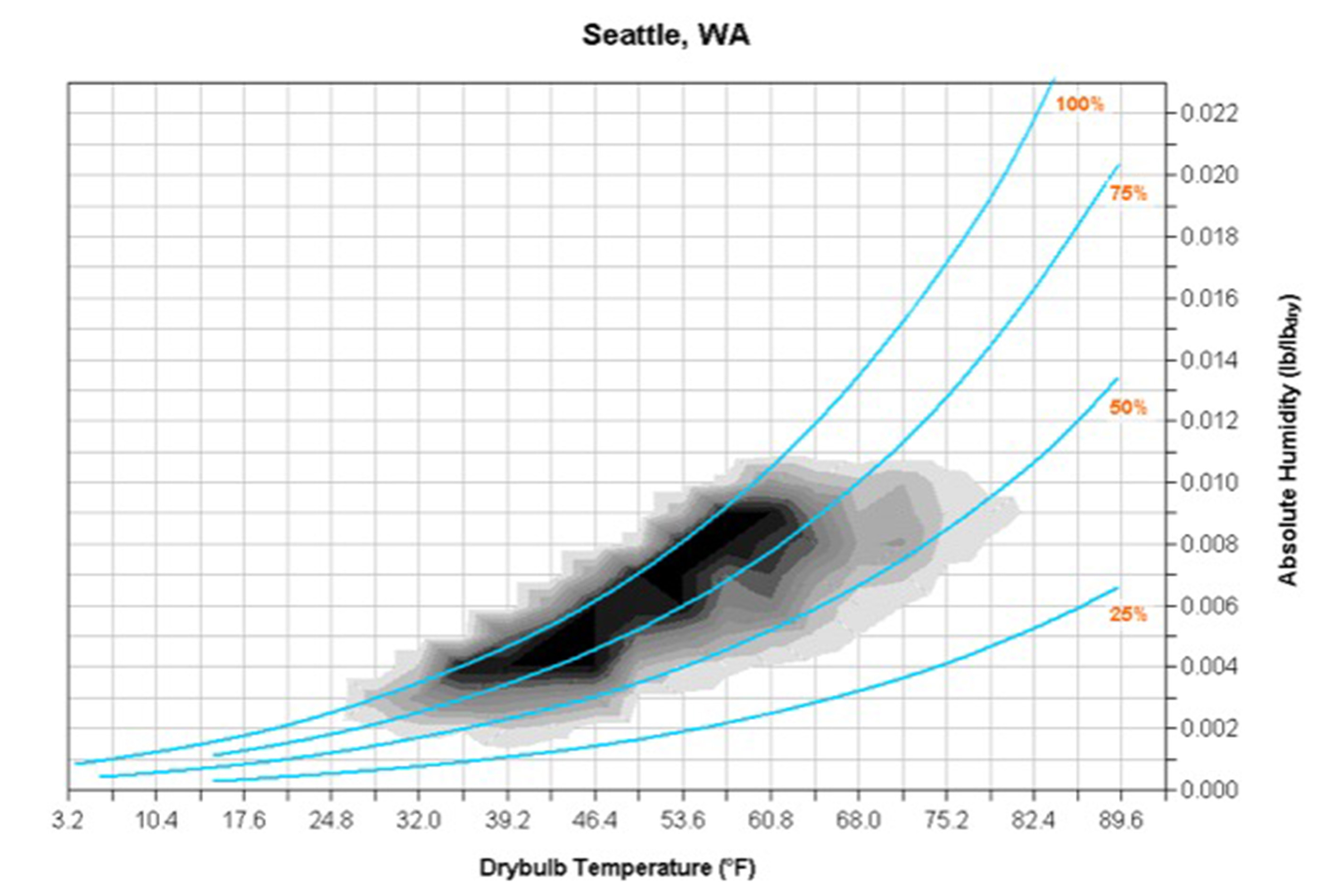

The external hygrothermal loads can be narrowed beyond the “regional”. Schumacher[3] developed a graphical approach combining the psychrometric chart with hourly climate data. Check out Figure 5a, 5b, 5c, and 5d for Los Angeles, Minneapolis, Las Vegas and Seattle respectively. This is what you get when you plot 8760 points on a psychrometric chart representing hourly temperature and relative humidity for an entire year.[4]

Figure 5: “Canadian Vitruvius” – Schumacher combining the psychrometric chart with hourly climate data…

What is going on inside establishes the internal environmental load. A warehouse is different than an apartment. An apartment is different than a hospital. The different internal environmental loads can be divided into interior climate classes based on temperature, humidity and air pressure.

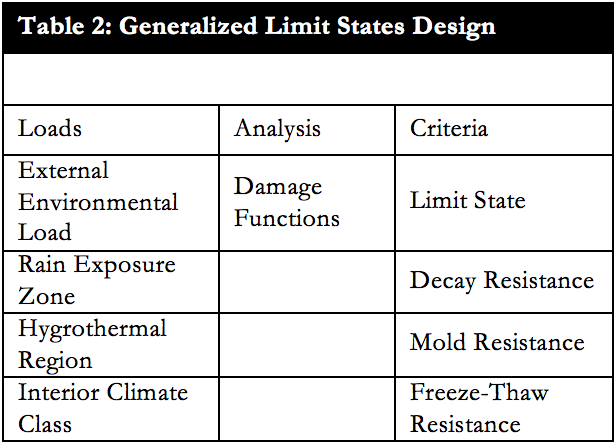

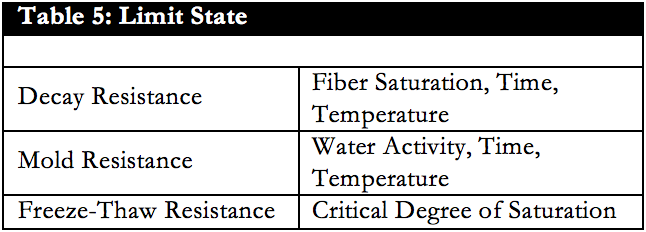

The “loads” establish the necessary “load resistance”. The “load resistance” needs to exceed a “limiting state”. Structural engineers recognize this approach as “limit states design”. In structural engineering a “limit state” would consider compressive strength, shear, tensile strength, bending moment and so on. In hygrothermal analysis a “limit state” would consider mold, decay, corrosion, freeze-thaw and so on. I call the approach “generalized limit states design” – with both apologies and credit to the structural engineering community (Table 2).[5]

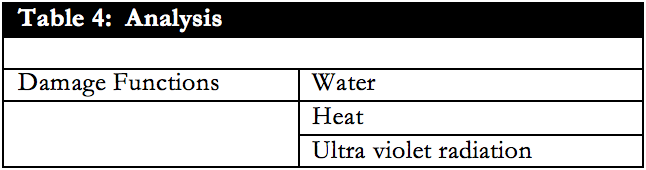

The environmental loads are listed in Table 3. The analysis parameters are listed in Table 4 and the limit states are listed in Table 5.

Analysis parameters? Think “things that trash other things”. In other words “damage functions”. The big three are water, heat, and ultra-violet radiation. Of the three, water is the worst.[6] Water movement cannot be understood without also simultaneously looking at heat flow – hence the term “hygrothermal analysis”.

The big question in hygrothermal analysis is how wet can something be for how long before you get into trouble? And of course the answer is “it depends” and no one can agree.[7] Things are different now. We are no longer building buildings out of rocks and 1,000 year old trees.

We are building out of engineered wood which is pretty much an insult to both engineers and to wood. I call it “was wood”. It was wood once…but not anymore. We don’t even see plywood much anymore. Oriented strand board (OSB) is ubiquitous (Photograph 1 and Photograph 2). I call OSB the spam of wood. I call spam the OSB of luncheon meats…. Back in the old days we used to go to places called forests and cut trees down and cut them in to boards. We would take these boards and build things called boats and put them in the water and sail them around the world. Try doing that with OSB.

Photograph 1: Oriented Strand Board – take a fast growing “teenager” tree and flake it, add the Colonel’s eleven secret herbs and spices, smoosh it together under heat and pressure and coat it with “water stay away stuff”.(c) Matthias Kabel from the Wikipedia Commons; https://en.wikipedia.org/wiki/Oriented_strand_board#/media/File:OSB_prod...

Photograph 2: Engineered Wood – Get used to it. It is not plywood. It is not a 1,000 year old tree. But it does work if you control the micro environment it sees. This is an entirely different way of looking at things. Back in the day we would change the material to suit a hostile environment. Today we have to change the environment to suit the material.(c) C. Sander from the Wikipedia Commons; https://en.wikipedia.org/wiki/File:OSB-Platte.jpg

It gets worse. We are insulating. Yup. And not just a little. A lot. And probably will be adding even more. Not much energy available to dry things if they get wet. We used to have so much energy flow across a wall assembly that it was “freeze dried” in the winter and “kiln dried” in the summer. The consequences only now are being appreciated. There is no such thing as a free thermodynamic lunch.

So what are the odds of going back to uninsulated assemblies built out of rocks and 1,000 year old trees? Not going to happen. We are learning to love engineered wood and are coming to terms with the reduced energy flow. We are developing the analysis parameters and the safety factors based on experience, observation and experiment. It has not been easy. Ugly is a word that comes to mind. Sometimes we get it right. Sometimes we get it wrong (Photograph 3).

Photograph 3: Getting It Wrong – Water sensitive material in a highly insulated assembly with poor water management and a low drying potential. We needed a “pan flashing” under the window and a water control layer with a drainage gap over the OSB to control the wetting and no interior vapor barrier to permit inward drying. Can we say the 1800’s are calling with your safety factor….

Out of the hygrothermal analysis come “performance metrics” such as windows requiring to meet specific water resistance when tested according to ASTM E1105 – Standard Test Method for Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls, by Uniform or Cyclic Static Air Pressure Difference at a pressure difference of 150 Pa or a building enclosure requiring to meet an air leakage resistance of 2.0 l/s/m2 @ 75 Pa when tested according to ASTM E779 – Standard Test Method for Determining Air Leakage Rate by Fan Pressurization.

Note that the “performance metrics” should be based on analysis and limit states. And that is the rub. We are struggling with the analysis and we can’t agree on the limit states and the safety factors. Where is Queen Victoria when you need her?[8]

References:

Hutcheon, N.B., 1953. “Fundamental Consideration in the Design of Exterior Walls for Buildings”. NRC Paper No. 3087, DBR No. 37. Division of Building Research, National Research Council of Canada, Ottawa.

Lstiburek, J.W., Moisture Control for Buildings, ASHRAE Journal, February, 2002.

Photograph 1 Image Source; (c) Matthias Kabel from the Wikipedia Commons; https://en.wikipedia.org/wiki/Oriented_strand_board#/media/File:OSB_production.jpg

Photograph 2 Image Source; (c) C. Sander from the Wikipedia Commons; https://en.wikipedia.org/wiki/File:OSB-Platte.jpg

[1] Hutcheon, N.B., 1953. “Fundamental Consideration in the Design of Exterior Walls for Buildings”. NRC Paper No. 3087, DBR No. 37. Division of Building Research, National Research Council of Canada, Ottawa.

[2] Thirty five years ago John Timusk said I needed to read about a dead guy named Marcus Vitruvius Pollio (c.90 -20 B.C.E.). Apparently both engineers and architects claim him as one of theirs. I loved the guy right away…check out his words… “Firmness, Commodity, Delight. These are properly designed, when due regard is had to the country and climate in which they are erected. For the method of building which is suited to Egypt would be very improper in Spain, and that in use in Pontus would be absurd at Rome…” At the same time Gus Handegord said I needed to pick up a geography text and check out a Russian-German guy by the name of Wladimir Peter Koppen (1846 – 1940). Koppen developed a climate classification system based on vegetation. Different climates lead to different plants. Why not let the plant growth define the climate? Observe the plants. Obvious when you think about it. Not obvious when Koppen first proposed it. In their own way John and Gus were telling me to observe the buildings. With Vitruvius looking over one shoulder and Koppen looking over the other I drew Figure 2 and got it adopted by the Department of Energy Building America Program. Out of Figure 2 the DOE folks at Pacific Northwest National Laboratory drew Figure 4 which got adopted by the model codes. Big time thanks to Todd Taylor who guided it through the code process. Who would have guessed that Vitruvius and Koppen would end up in the IBC, IRC and the IECC with help from Timusk and Handegord.

[3] Chris Schumacher, Waterloo, Ontario. Chris has a background in both architecture and engineering. Not a lot of folks around with a classic education in both professions. A modern day Vitruvius, without the Latin. Atta boy Chris.

[4] Yes, I know all you have to do is input hourly climate data into a simulation, so why bother with a graph like this? Let me tell you why you bother. You can’t visualize hourly data for a year in a print out. The computer causes you to lose “the feel for the problem”. This helps you visualize the data. Compare Las Vegas to Seattle.

[5] Lstiburek, J.W., Moisture Control for Buildings, ASHRAE Journal, February, 2002. Yes, I cited myself.

[6] Often misspelled as “wurst”….which is why Germans are so good at hygrothermal analysis….

[7] Just like the early days of structural engineering. The structural folks handled the uncertainty with “safety factors”. The safety factors varied depending of the “criticality” of the element or component. Judgement based on experience, observation, and experiment informed the practitioner. Structural engineering today is still a phenomological oriented field dominated by experimentally derived coefficients. And it works exceptionally well. Buildings and bridges don’t fall down or blow away. They used to. But not anymore. Not for the past century. It was an exciting time for structural engineers way back then. Not much happens anymore structurally. You want excitement, talk to an engineer who does hygrothermal analysis. Nothing seems to work and we keep guessing…

[8] There is an excellent discussion on safety factors and structural analysis by Alasdair Beal “A History of Safety Factors”, The Structural Engineer 89 (20) October 2011. The “pull quote” is “In the world of computer calculations, a safety factor is a strange thing: loads and stresses are calculated to 0.01 percent precision – and then a “safety margin” of 50-100 percent is added to create the final design…..How much of this is science and how much is “black art”? Back in the 1800’s when structural engineers lived with cast iron and wrought iron they had to come to terms with “variable and vulnerable” materials. Legend has it that Queen Victoria created a Royal Commission that brought all the leading practitioners together from around the world to sort all of this out. Replace “cast iron” and “wrought iron” with OSB and paper faced gypsum and move from the 19th century to the 21st and you get an understanding of the problem. We need a Queen Victoria. I don’t think a prince will do. The Prince I liked was a musician….