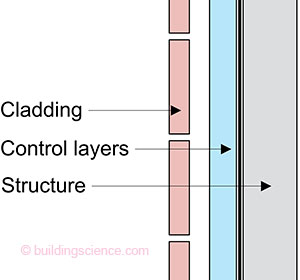

With the “perfect wall” we were here way back when (BSI-001: The Perfect Wall). The perfect wall has four control layers outside of the structure:

- a water control layer

- an air control layer

- a vapor control layer

- a thermal control layer

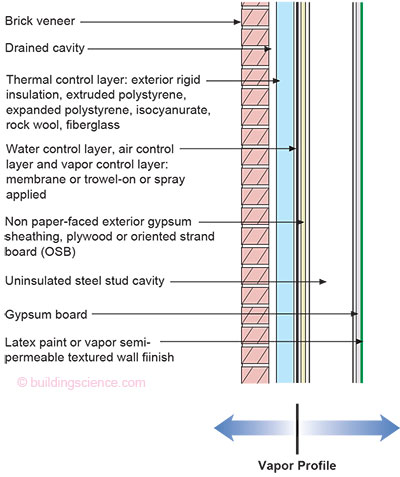

These are typically covered with a drained cladding (Figure 1). No mystery here. The most common manifestation of the perfect wall is a steel framed wall sheathed with exterior gypsum board (Figure 2).

Figure 1: Perfect Wall—Control layers located exterior to the structure.

Figure 2: Typical Perfect Wall—The most common manifestation of the perfect wall is a steel framed wall sheathed with exterior gypsum board. Note the vapor profile at the bottom. Drying occurs to the interior from the bold line and to the exterior from the bold line in all climates.

The control layers are listed in order of importance. All are important, but not equally important. The ranking comes from historic experience and the underlying physics. Controlling water in the liquid form (rain and ground water) has been the focus of master builders and architects for generations. Controlling air is a much more recent focus – less than a century. When considering water and air I can pretty much assure you I have never gotten a call at 2 a.m. from an angry client yelling “my building is leaking air…my building is leaking air”. The corollary, however, is too often true for many in the industry. There should be no doubt, the water control layer is much more important than the air control layer. Take note ABAA1.

Controlling vapor is even more recent – only a generation or two. Air movement transports significantly more water in the vapor form than does vapor diffusion and therefore air control is more important than the control of molecular water vapor transport “vapor diffusion”. “Air barriers” are more important than “vapor barriers”.

Thermal control dates back millenniums – but getting it wrong has rarely led to durability failures. The thermal control layer failures have been typically limited to comfort issues and operating cost issues. Hence, thermal control layers are listed last on the control layer “priority” list.2

In the last decade we have gotten pretty good at combining the water control layer, air control layer and vapor control layer into a single layer that can be a film or coating or membrane or a sheet good. We have also gotten pretty good at wrapping the exterior of all this with the fourth control layer – the thermal control layer.

This configuration, with the thermal control layer outboard of the water, air and vapor control layers, allows the assembly to be constructed in all climate zones: cold, mixed, hot and humid or dry. Even better, this configuration allows this assembly to enclose all interior environments in all climate zones: office, commercial, residential, institutional, pools, museums, art galleries, data processing centers. The sole exception being refrigerated buildings and cold storage facilities. In such assemblies the location of the thermal control layer is “flipped” with the other control layers – the thermal control layer now becomes located on the interior of the other three control layers. More about this later.

In cold climates locating the vapor control layer on the interior of the thermal control layer results in this layer remaining warm therefore controlling condensation from occurring due to interior moisture sources.

In hot climates locating the vapor control layer on the exterior of the structure allows the drainage of condensation to the exterior – condensation that may occur on the exterior surface of the control layer due to exterior moisture surfaces. This condensed water is handled in the same manner as penetrating rainwater. Note that the water control layer and vapor control layer are in the same location and are typically the same material.

In mixed climates the configuration addresses interior moisture loads during the heating season in the same manner a similar assembly addresses interior moisture loads in cold climates. During the cooling season the configuration addresses exterior moisture loads in the same manner a similar assembly addresses exterior moisture loads in hot climates.

Note the vapor profile at the bottom of Figure 2. Drying occurs to the interior from the bold line and to the exterior from the bold line in all climates. For this reason, this configuration or assembly is referred to as the “universal wall” or the “perfect wall”. It works in all climate zones for all interior environmental conditions with the exception noted.

The cladding is drained. Again, we have been here before (BSI-057: Hockey Pucks & Hydrostatic Pressure). The function of the drainage is to control hydrostatic pressure that may result from penetrating rainwater.

In this assembly a myriad of products work successfully. Almost any exterior insulation works and almost any sheet good, spray system or trowel applied membrane works.

Channeling Joseph Haydn

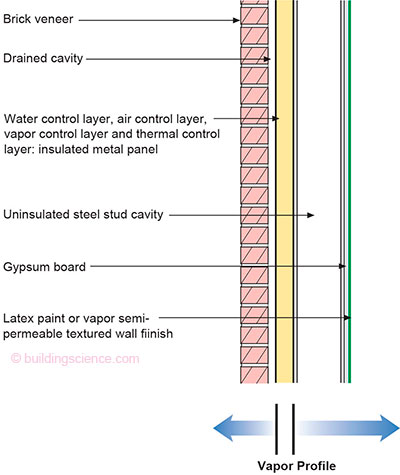

All is good with the universe and we are done right? Well, no. There are variations on a theme3. One of the variations of the “perfect wall” is an insulated metal panel.

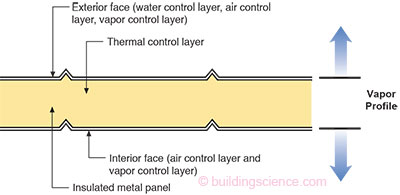

Insulated metal panel systems are a “pre-manufactured” version of a “perfect wall” (Figure 3). With insulated metal panel systems the vapor profile is slightly altered from that of a traditional “perfect wall”. Drying to the exterior occurs from the exterior face of the insulated metal panel system in all climate zones. Drying to the interior occurs from the interior face of the insulated metal panel system in all climate zones.

Figure 3: Insulated Metal Panel—A “pre-manufactured” version of a “perfect wall”. With insulated metal panel systems the vapor profile is slightly altered from that of a traditional “perfect wall”. Drying to the exterior occurs from the exterior face of the insulated metal panel system in all climate zones. Drying to the interior occurs from the interior face of the insulated metal panel system in all climate zones.

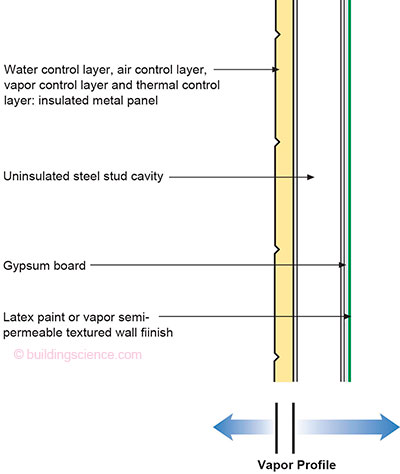

Insulated metal panel systems get even simpler. Check out Figure 4. The traditional cladding is omitted and the exterior face of the insulated panel becomes the cladding. With this approach insulated metal panel systems “channel” precast concrete panel systems. The results are impressive (Photograph 1 and Photograph 2).

Figure 4: “Face-Clad”—The traditional cladding is omitted and the exterior face of the insulated panel becomes the cladding. With this approach insulated metal panel systems “channel” precast concrete panel systems.

Photograph 1: Insulated Metal Panel System I—Concrete frame infilled with metal framing and clad with insulated metal panels.

Photograph 2: Insulated Metal Panel System II—Completed building with both insulated metal panels and glazing installed.

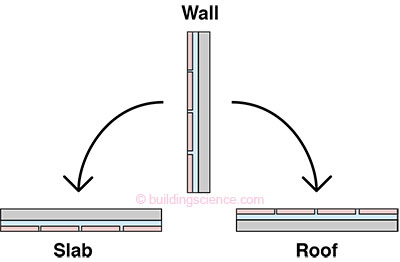

From our previous look at the perfect wall we noted that the same approaches can be applied to roofs – the argument being that similar loads and the same laws of physics apply (Figure 5).

Figure 5: Walls Are Roofs Are Walls—The same approaches can be applied to both walls and roofs – the argument being that similar loads and the same laws of physics apply.

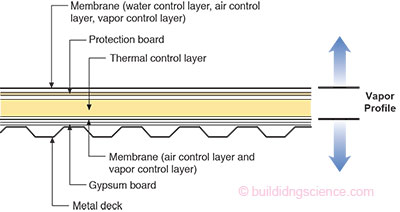

The traditional configuration for the control layers of a compact roof assembly is presented in Figure 6. Control layers are provided above and below the thermal control layer. The typical roof membrane functions as the water control layer, an air control layer and a vapor control layer above the thermal control layer – the “insulation”. A second membrane or layer or layers are provided below the thermal control layer – the “insulation” – and the function of this membrane or layers is to function as an air control layer and vapor control layer. The intent is to keep the “rain” and “air” and “vapor” from getting into the assembly from the top (“outside”) and to keep the “air” and “vapor” from getting into the thermal control layer from the bottom (“inside”). This configuration also works in all climate zones and for all interior environmental conditions – even for refrigerated buildings and cold storage facilities.

Note the vapor profile of the compact roof assembly. Drying occurs to the interior from the lower membrane and to the exterior from the upper roof membrane in all climate zones.

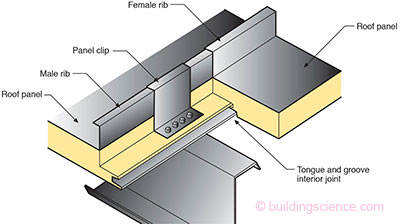

Insulated metal panel roof systems are a “pre-manufactured” version of a compact roof assembly (Figure 7). With insulated metal panel roof systems the vapor profile is identical to that of a traditional compact roof. Accordingly, as is the case for traditional compact roofs, insulated metal panel roof systems also work for refrigerated buildings and cold storage facilities in all climates.

Figure 6: Compact Roof Assembly—Control layers are provided above and below the thermal control layer. The typical roof membrane functions as the water control layer, an air control layer and a vapor control layer above the thermal control layer – the “insulation”. A second membrane or layer or layers are provided below the thermal control layer – the “insulation” – and the function of this membrane or layers is to function as an air control layer and vapor control layer. The intent is to keep the “rain” and “air” and “vapor” from getting into the assembly from the top (“outside”) and to keep the “air” and “vapor” from getting into the thermal control layer from the bottom (“inside”).

Figure 7: Insulated Metal Panel Roof—A “pre-manufactured” version of a compact roof assembly. With insulated metal panel roof systems the vapor profile is identical to that of a traditional compact roof. Accordingly, as is the case for traditional compact roofs, insulated metal panel roof systems also work for refrigerated buildings and cold storage facilities in all climates.

It’s All About the Joints

In panel systems joints are required to meet the same control requirements, as assemblies are required to meet in the field of the wall or the field of the roof – namely provide:

- Water control continuity

- Air control continuity

- Vapor control continuity

- Thermal control continuity

panel. The air control of a panel should be connected to the air control of an adjacent panel. The vapor control of a panel should be connected to the vapor control of an adjacent panel. And finally the thermal control of a panel should be connected to the thermal control of an adjacent panel.

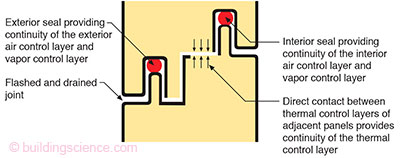

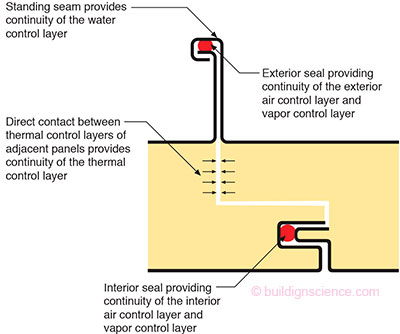

Figure 8 illustrates the fundamental principles for insulated metal wall panels. Water control layer continuity is provided by a “flashed” and drained joint. The upward “tongue” of the lower panel functions similarly to the elevated vertical leg of a “metal flashing”. The exterior horizontal gap between upper and lower panels facilitates drainage at the panel joint (Photograph 3).

Figure 8: Wall Panel Joint—Water control layer continuity is provided by a “flashed” and drained joint. The upward “tongue” of the lower panel functions similarly to the elevated vertical leg of a “metal flashing”. The exterior horizontal gap between upper and lower panels facilitates drainage at the panel joint. Air and vapor control continuity is provided by sealant joints. Note that insulated panel systems have both interior and exterior air control and vapor control layers. As such they require both an interior and exterior seal. Thermal control continuity is provided by direct contract of the adjacent panel thermal control layers.

Photograph 3: Insulated Metal Wall Panels—The upward “tongue” of the lower panel functions similarly to the elevated vertical leg of a “metal flashing”.

Air and vapor control continuity is provided by sealant joints. Note that insulated panel systems have both interior and exterior air control and vapor control layers. In many insulated metal panel assemblies where wind, rain and exterior humidity loads are low the outer seal is omitted. In refrigerated buildings the inner seal is omitted to allow the joint to dry inwards.

Thermal control continuity is provided by direct contact between the thermal control layers of adjacent panels. The thermally conductive exterior and interior metal panel faces are broken at panel edges. The metal faces do not wrap continuously around panel edges thereby providing a thermal break.

Figure 9 illustrates the fundamental principles for roof panels. Water control is provided by a “standing seam” and gravity (Photograph 4 and Photograph 5). Air and vapor and thermal control are addressed similarly to those of wall panels.

Figure 9: Roof Panel Joint—Water control is provided by a “standing seam” and gravity. Air and vapor and thermal control are addressed similarly to those of wall panels.

Photograph 4: Insulated Metal Roof Panel—Installation of roof panels “crimping” the “standing seams”.

Photograph 5: Insulated Metal Roof Panel—Positioning the roof panel during installation.

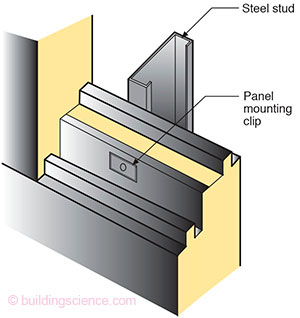

Check out Figure 10 for wall panels and Figure 11 for roof panels. Note the panel mounting clips for both wall assemblies and roof assemblies are attached over the thermal control layer where the thermal control layer acts as a thermal break.

Figure 10: Wall Panel Mounting Clip—The thermally conductive exterior and interior metal panel faces are broken at panel edges. The metal faces do not wrap continuously around panel edges thereby providing a thermal break.

Figure 11: Roof Panel Mounting Clip—Again, as for wall panels, the thermally conductive exterior and interior metal panel faces are broken at panel edges.

Photograph 6: Retrofit Metal Panel—With retrofit approaches it is common to apply a fluid water and air control layer directly to the masonry. Note the sheet membrane transition between the field of the wall and the replacement glazing system.

Photograph 7: Retrofit Metal Panel—Insulated metal panels only provide the thermal control function and cladding function.

Pan Out?

Panel manufacturers over the past couple of generations have innovated their way into building enclosure systems that work in all climates and even more impressive—work with pretty much any interior condition from refrigerated buildings, ice rinks, natatoriums to standard commercial buildings. Apparently the systems have “panned out”4.

Footnotes

- ABAA stands for “Air Barrier Association of America” not to be confused with ABBA the Swedish musical group. I am of the opinion we should have had a WBAA “Water Barrier Association of America” before we had an ABAA but I have learned the hard way that physics and logic should never get in the way of marketing.

- We can also calculate and model the thermal control layer much better than the other control layers. If we can calculate them and they are unimportant the building code tends to obsess over them. The code is full of U-values and R-values and pretty much silent on water control except for a generalized “be good” and “good luck”.

- Variations on a Theme by Joseph Haydn was composed by Johannes Brahms. A fabulous piece of work. Brahms attributed the theme – the melody—to Haydn and credited him accordingly. Although, today, there is doubt that Haydn was the original source. So for us the “Perfect Wall” is the melody of building science and it is attributed to Professor Neil Hutcheon.

- Prospectors separate and recover valuable minerals by swirling dirt or crushed rock in a pan of water. Hence “pan out” has come to mean “to succeed”.