Dirty Harry Does Insulation[1]

“A good insulation always knows its limitations….”

After all these decades thermal performance should be pretty non-controversial. How complicated can it be to insulate a building and make it airtight? The physics is pretty straightforward. But then you get salespeople and marketing people involved and the physics gets twisted and people get annoyed[2]. For the record I like all insulations…yup…all of them…I think they are all good…but they all have limitations…

What is nice about where we are right now…after all these decades…is that we have performance requirements specified in the Model Codes for thermal resistance for roofs, walls, and foundations….and we have airtightness performance requirements specified in the Model Codes for air barrier materials, air barrier assemblies and air barrier enclosures.[3] We also have airtightness performance requirements for duct distribution systems in the Model Codes. Buildings are required to be airtight…and are tested for compliance.[4] Ducts are required to be airtight and air tested for compliance.[5]

In terms of insulations and insulation systems install them correctly and they provide the thermal resistance expected. Let me repeat that, install them correctly and they work.

Here is something that should be obvious… It is a very, very bad idea to try to trade off thermal resistance for increased airtightness because the Model Code minimum airtightness is already so low. Let me repeat, it does not matter because we are already so “tight”. We build tight…and sometimes “ventilate right” (“BSI-069: Unintended Consequences Suck”, June 2013 and “BSI-070: First Deal with Manure & Then Don’t Suck”, June 2014).

Here is another thing that is obvious…some insulations can also act as “air control layers” (aka “air barriers”)…in addition to acting as “thermal control layers”. It gets even more interesting….some can also act as “vapor control layers”…or not….and some can also act as “water control layers” (aka “water resistive barriers (wrb’s)” or “drainage planes”…). Some can act as all of the above….some can’t. Let’s look at a bunch of common insulations and see what they can do…and what they can’t do.

Foil faced polyisocyanurate boards installed on the exterior of framing with their joints taped/sealed can act as the water control layer, air control layer, vapor control layer and thermal control layer….all four control layers (Photograph 1). So can extruded polystyrene (XPS) boards (Photograph 2)

Photograph 1: Foil Faced Polyisocyanurate Boards – The rigid insulation boards are installed on the exterior of framing with their joints taped/sealed and act as the water control layer, air control layer, vapor control layer and thermal control layer….all four control layers.

Photograph 2: Extruded Polystyrene (XPS) Boards - The rigid insulation boards are installed on the exterior of framing with their joints taped/sealed and act as the water control layer, air control layer, vapor control layer and thermal control layer….all four control layers.

Photograph 3: Mineral Wool Board Insulation – The insulation boards installed on the exterior of framing can act as the thermal control layer…but they need to be coupled with a water control layer, air control layer and vapor control layer…mineral wool board insulation can do only one of the control layers.

Let’s look structural insulated panels (SIP’s). They can act as the air control layer, vapor control layer and thermal control layer (Photograph 4). They need to have a water control layer installed on their exterior.

Photograph 4: Structural Insulated Panels (SIP’s) - They can act as the air control layer, vapor control layer and thermal control layer but not the water control layer. They need to have a water control layer installed on their exterior.

How about insulated concrete forms (ICF’s)? They can act as the air control layer, vapor control layer and thermal control layer (Photograph 5). They need to have a water control layer installed on their exterior or a cladding such as polymer based (PB) stucco directly attached to their exterior face creating a barrier wall mass assembly (“BSI-040: High Rise Igloos”, October 2010).

Photograph 5: Insulated Concrete Forms (ICF’s) - They can act as the air control layer, vapor control layer and thermal control layer. They need to have a water control layer installed on their exterior or a cladding such as polymer based (PB) stucco directly attached to their exterior face creating a barrier wall mass assembly.

Now let’s look at spray polyurethane foam. When you spray closed cell, high density spray polyurethane foam (ccSPF) on the exterior of gypsum sheathing or plywood or OSB it can act as the water control layer, air control layer, vapor control layer and thermal control layer (Photograph 6)….all four control layers (“BSI-048: Exterior Spray Foam”, April 2011). Works for roofs as well – a fluid applied roofing membrane can be applied directly to the ccSPF. The Louisiana Superdome was successfully repaired with this approach after Hurricane Katrina (Photograph 7) (“How Not to Build Roofs”, ASHRAE Journal, March, 2008).

Photograph 6: Spray Polyurethane Foam - When you spray closed cell, high density spray polyurethane foam (ccSPF) on the exterior of gypsum sheathing or plywood or OSB it can act as the water control layer, air control layer, vapor control layer and thermal control layer….all four control layers

Photograph 7: Spray Polyurethane Foam Roofing – A fluid applied roofing membrane can be applied directly to the ccSPF. The Louisiana Superdome was successfully repaired with this approach after Hurricane Katrina.

Open cell, low density spray foam (ocSPF) if applied on the exterior of wall assemblies can’t act as the water control layer – a fluid applied water control layer needs to be applied over its exterior surface.

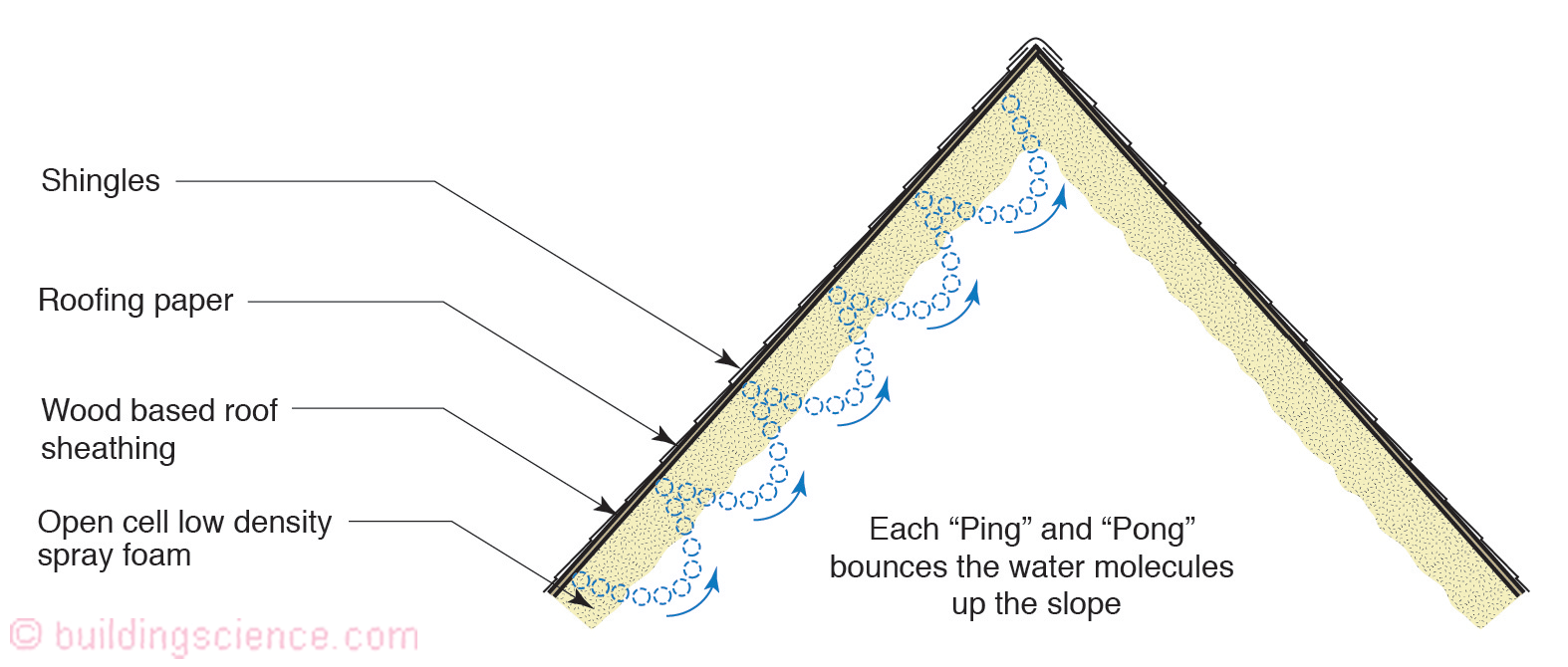

When you spray ccSPF into wall cavities from the interior the ccSPF can act as the air control layer, vapor control layer and thermal control layer (“BSI-116: Interior Spray Foam”, April 2020). When you spray ocSPF into wall cavities from the interior the ocSPF can act as the air control layer and thermal control layer. It can’t act as the vapor control layer – it is too vapor open. This is a problem when you spray ocSPF on the underside of roof/attic assemblies (Photograph 8) you can end up with problems (“BSI-016: Ping Pong Water and the Chemical Engineer”, October 2016). Water vapor from the interior passes up through the ocSPF and is stored in the wood based roof sheathing – and then driven out by solar radiation. In and then out…in and then out…a “ping” followed by a “pong” leading to an increase in moisture accumulating at the ridge (Figure 1)….requiring a means of moisture removal….either air supply and return from the house or a dehumidifier. Note that this also happens with fiberglass (Photograph 9), mineral wool and cellulose…all of these insulations also require either air supply and return from the house coupled with a “vapor diffusion port” or a dehumidifier (“BSI-088: Venting Vapor”, July 2015). Further note that none of this is an issue with ccSPF. Let me repeat, none of this is an issue with ccSPF….because it is not vapor “open”.

Photograph 8: Open Cell Spray Polyurethane Foam (ocSFP) - When you spray ocSPF into wall cavities from the interior the ocSPF can act as the air control layer and thermal control layer. It can’t act as the vapor control layer – it is too vapor open. This is a problem when you spray ocSPF on the underside of roof/attic assemblies you can end up with problems (“Ping Pong Water”).

Figure 1: “Ping Pong Water” - Water vapor from the interior passes up through the ocSPF and is stored in the wood based roof sheathing – and then driven out by solar radiation. In and then out…in and then out…a “ping” followed by a “pong” leading to an increase in moisture accumulating at the ridge requiring a means of moisture removal….either air supply and return from the house or a dehumidifier.

Photograph 9: Fiberglass and Mineral Wool and Cellulose Underside Roof Deck Insulation - Water vapor from the interior passes up through the vapor open insulation and is stored in the wood based roof sheathing – and then driven out by solar radiation. In and then out…in and then out…a “ping” followed by a “pong” leading to an increase in moisture accumulating at the ridge requiring a means of moisture removal…. either air supply and return from the house coupled with a “vapor diffusion port” or a dehumidifier

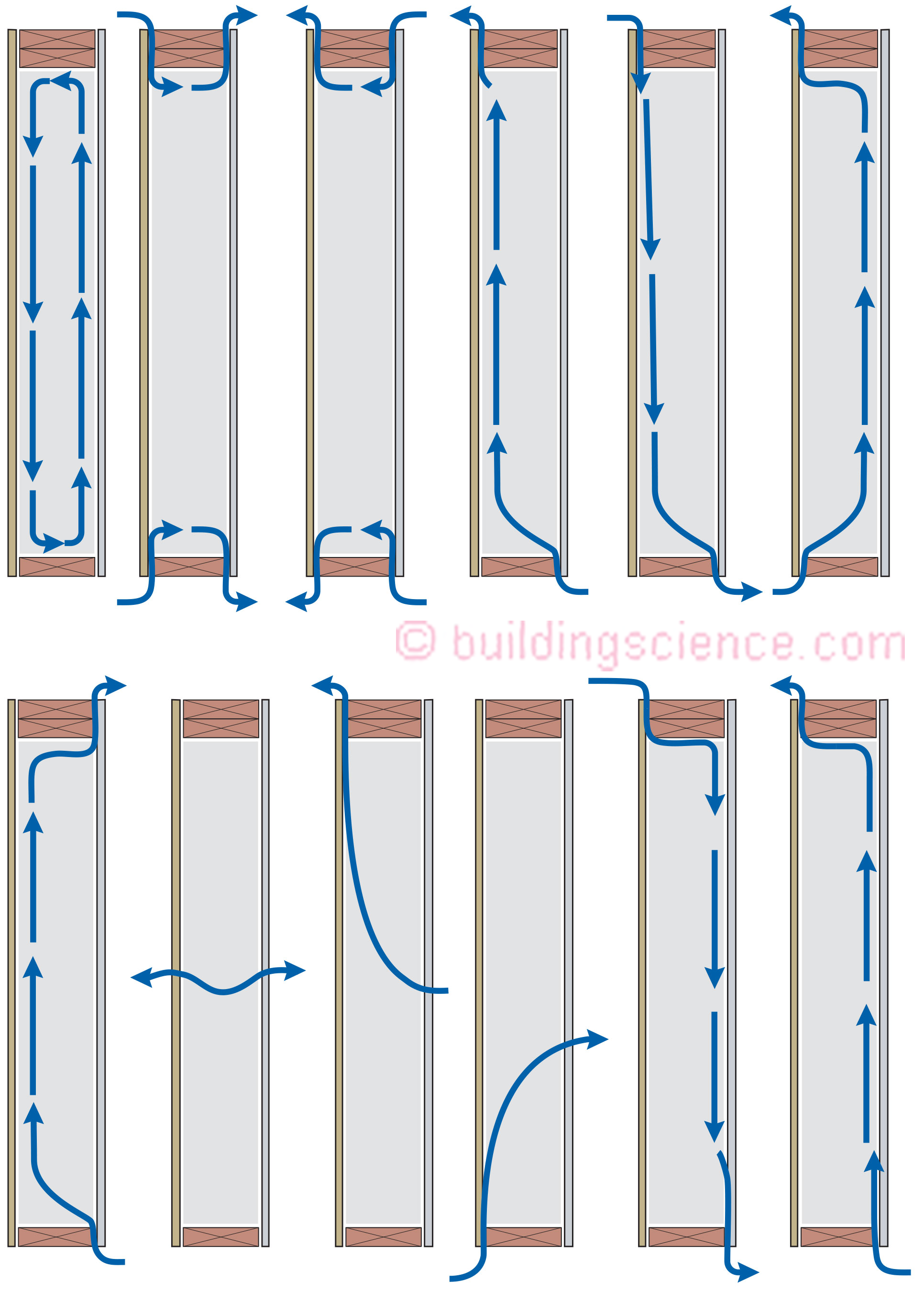

On to fiberglass and mineral wool batts installed in wall cavities, roof cavities, on the ceilings of attics or on the underside of roof/attic sheathig. They obviously can’t act as the water control layer, the air control layer or the vapor control layer. They can act as the thermal control layer if airflow through them is limited or controlled (Photograph 10 and Photograph 11). We learned this with our “Thermal Metric Project” (see References). In fact, the Thermal Metric Project showed that all cavity insulations functioned if they were combined with air control layers and if convection was controlled (Figure 2). Let me be specific and obvious – if batts are installed and fitted “tightly” without voids they work (“BSI-089: WUFI-Barking Up the Wrong Tree?”, November 2015). Additionally, in roof/attic applications wind-washing must be controlled (“BSI-064: Bobby Darin and Thermal Performance”, October 2012).

Photograph 10: Fiberglass and Mineral Wool Batts – When they are installed in wall cavities, roof cavities, on the ceilings of attics or on the underside of roof/attic sheathing they can’t act as the water control layer, the air control layer or the vapor control layer. They can act as the thermal control layer if airflow through them is limited or controlled.

Photograph 11: Faced Insulation Batts – Air flow and convection can be effectively controlled by facers adhered to batt insulation. Note that faced insulation batts should have the facers installed to the “face” of the stud framing – not “inset stapled”. Inset stapling creates voids and air channels that can lead to convective loops and a loss of thermal resistance.

Figure 2: Cavity Insulation Airflow Pathways – There are 12 possible airflow pathways that can reduce the thermal resistance of cavity insulations. Cavity insulations can act as effective thermal control layers. The Thermal Metric Project showed that all cavity insulations functioned if they were combined with air control layers and if convection was controlled. Let me be specific and obvious – if batts are installed and fitted “tightly” without voids they work.

How about cellulose…the netted and damp spray kind? They can only act as the thermal control layer (Photograph 12). They can’t act as the air control layer – despite what folks say (“Don’t be Dense With Insulation”, ASHRAE Journal, August 2010). Same with netted blown fiberglass.

Photograph 12: Netted and Damp Spray Cellulose - They can only act as the thermal control layer. They can’t act as the air control layer or the vapor control layer. Same with netted blown fiberglass.

What else do we want to look at? Lot’s of stuff…but one more biggie…fire. Lot’s of insulations burn, lot’s do not. Those that do not can be made to work (“BSI-098: Great Fire of London”, August 2017). What about embodied energy, carbon footprint, global warming potential? Ah, save that for another day[6]

Now to sales people and marketing people….they can’t help themselves. I got this argument years ago – and thought we crushed it – but alas no. Here goes….if I make my house airtight I don’t need as much insulation….. Or my insulation is so good it makes the house airtight so I don’t need as much insulation. This argument typically comes from people whose insulation is more expensive than their competitors – so to compete on a cost basis they want to reduce the amount of insulation. With todays’ levels of airtightness and duct tightness you can’t reduce thermal insulation and expect the house to perform the same.

The first time I had to deal with this was in Florida when I was using low density spray polyurethane foam to create conditioned attics. Yes, the entire house became more airtight. Yeah!!! The roof deck/insulation layer became the air barrier and was connected to the top of the walls. But you could also get there taping/sealing the joints of the plywood or OSB roof sheathing and installing sealed wood blocking between the rafter tails or the roof trusses. You did not need spray foam to get the airtightness. We showed this with fiberglass and mineral wool insulation (“BSI-088: Venting Vapor”, July 2015 and “Conditioned Unvented Attics & Unconditioned Unvented Attics”, ASHRAE Journal, June 2020).

It is amazing how soon foam sales people and marketing people forget one of the code arguments that argued against unvented conditioned attics….when you move the thermal layer from the ceiling to the underside of the roof the surface area of heat gain/heat loss goes up 30 to 40 percent[7]…. I had to argue aggressively to not have spray foam roofs penalized because of the increase in surface area. Remember the big issue was leaky ductwork in vented attics… By moving the insulation layer to the underside of the roof deck I argued that the ducts were now “inside” and if they now leaked it wouldn’t matter.

The counter code argument was…who cares…we can make ductwork tight so it does not leak….yes...true...ouch. Ducts today are tight wherever they are (we were here before “BSI-077: Cool Hand Luke Meets Attics, July 2015). But I won the battle by saying even tight R-6 ducts were pretty bad in a vented attic when they are above all that R-30 ceiling insulation (now it is R-38 and going up) exposed to all that radiation exchange from the underside of the roof deck…if I could just keep to R-30 on the underside of the roof deck and not be made to increase the thermal resistance of that layer the increase in surface area of heat gain/heat loss would be compensated for by the way more effective thermal performance of the ductwork that was no longer exposed to the radiation exchange.

And then the next battle was from the attic vent people who argued that vented attics and vented roofs were more energy efficient because all that airflow from the outside would cool the underside of the roof deck. Turned out that was not the case because for the airflow to be effective it had to be well coupled to the underside of the roof deck…the airflow was not sufficient to compensate for the radiation exchange between the underside of the roof deck and the top of the insulation layer on the ceiling. Sheesh….

I need to repeat once again….it was lucky to just break even thermally with unvented conditioned attics compared to vented unconditioned attics in the code arena. So now I chuckle in amazement when I hear the current argument….if I use spray foam on the underside of the roof deck the increase in airtightness is so significant I can therefor reduce the minimum Model Code thermal resistance roof insulation R-value by 20 or 30 percent.

Let me go back to the beginning….again…it is a very, very bad idea to try to trade off thermal resistance for increased airtightness because the Model Code minimum airtightness is already so low. Let me repeat, again, it does not matter because we are already so “tight”.

And guess what, let’s say the argument works….wait for it…guess what comes next? We are already dealing with the manufacturers of solar panels, battery storage and high efficiency geothermal systems saying who cares about thermal resistance and airtightness if you use our stuff…we can trade off building enclosure efficiency with solar collectors and conditioning system efficiency improvements…we don’t need all that airtightness and thermal insulation.

Sales people and marketing people who sell and market thermal insulation…be careful what you wish for…

Footnotes

[1] ”Dirty” Harry Callahan….”A good man always knows his limitations”…Magnum Force, 1973, Clint Eastwood as Harry Callahan…

[2] In the 1990’s I developed the technology behind unvented and conditioned roof assemblies using spray polyurethane foam (SPF) with help from the U.S. Department of Energy’s “Building America Program” and got it accepted by the Model Codes and managed to irritate the manufacturers of fiberglass, cellulose and mineral wool insulation. It was so bad I woke up one morning with a bag of fiberglass in my bed…Then in the mid 2000’s I developed the technology behind unvented and conditioned roof assemblies using fiberglass, cellulose, and mineral wool with help from the U.S. Department of Energy’s “Building America Program” and got it accepted by the Model Codes and managed to irritate the manufacturers of spray polyurethane foam (SPF) insulation. It was so bad….wait for it… I woke up one morning with cans of spray foam in my bed…

[3] These requirements came from my work also through the U.S. Department of Energy’s “Building America Program”. Air impermeable insulation is 0.02 l/s-m2 at 75 Pa – basically the leakage through gypsum board (aka “drywall”). Air barrier enclosures for buildings are 2.00 l/s-m2 at 75 Pa (“Understanding Air Barriers”, ASHRAE Journal, July 2005). Residentially, the Model Codes call out 3 ach@50 Pa for houses constructed in cold and mixed climates and 5 ach@50 Pa for houses constructed in hot climates. The reason for the difference between the climates is in cold and mixed climates we have basements- great places for ductwork and mechanical systems. Where we have slabs with vented attics and vented crawlspaces with vented attics with ductwork and mechanical systems in them it is not easy to get to 3 ach@ 50 Pa. Hence, the “push” to unvented and conditioned roof assemblies and unvented and conditioned attics and crawlspaces – easy to get to 3 ach@50 Pa. The problem is not leaky ducts but all those penetrations the ducts and boots go through.

[4] It is amazing when you think about this…in the 1980’s and 1990’s houses were 5 ach@50 Pa to 15 ach@50 Pa and now they are at 3 ach@50 Pa to 5 ach@50 Pa.

[5] It is even more amazing that in the 1980’s and 1990’s ductwork leakage was typically between 10 and 30 percent @25 Pa and now it is typically between 3 and 5 percent @25 Pa. Mineral wool board insulation installed on the exterior of framing can act as the thermal control layer…but it needs to be coupled with a water control layer, air control layer and vapor control layer Photograph 3)…it can do only one of the control layers (“BSI-108: Are We Sealing the Right Walls In Buildings?, Dec 2018”).

[6] I currently don’t have a bed big enough for all the insulation I would wake up with…For the record if we did tax accounting the way folks do carbon accounting the IRS would put us all in prison…

[7] It’s this Pythagoras and hypotenuse thing…

References

Understanding Air Barriers, ASHRAE Journal, July 2005.

https://www.buildingscience.com/documents/digests/bsd-104-understanding-air-barriers

The Thermal Metric Project, Building Science Corporation, January, 2013

https://www.buildingscience.com/documents/special/thermal-metric

The Thermal Metric Project – Summary Report, Building Science Corporation, June, 2015

20150618_thermal_metric_summary_report_-_june_2015_update.pdf