Brick veneers are essentially transparent to water. Wood clapboards, fiber cement siding, and vinyl siding also leak, each in its own special way. In the real world all claddings leak sooner or later. They always have, and they always will. When your cladding leaks, neither caulking nor sealants will keep water out of your building. So if all claddings leak, and all sealants and caulks fail, how can we keep buildings dry? By creating a water management system beneath the cladding: a continuous drainage plane with integrated flashings and weep holes, with an air space between the cladding and the drainage plane where water can flow. Reprinted from The Journal of Light Construction, March 2003.

In the top photo in Figure 1, next page, I'm conducting a sophisticated engineering test on the rain holdout characteristics of a cladding material. I'm spraying the brick veneer wall of a garage with a garden hose. I have a wager going with people inside the garage — I'm asking them to guess how long it will take, under the conditions of this test, for water to pass through the brick veneer. It's a multiple choice test: A) seconds, B) minutes, or C) hours.

The correct answer is A, between 15 and 30 seconds. Brick veneers are essentially transparent to water. We like to think, "Hey, brick is strong. It can handle water." And it can — in the sense that the water doesn't damage the brick. But brick is just like a sponge: It sucks water in by capillary action, holds some of it, and lets the rest drool out everywhere. Brick can protect our walls from many things, but water is not one of them.

Wood clapboards, fiber cement siding, and vinyl siding also leak, each in its own special way. People continue to put their faith in every kind of cladding material, but in the real world all claddings leak sooner or later. They always have, and they always will.

The common fallback strategy is to use caulks and sealants. But that's not the answer, either. Sealants do not span cracks, they cannot withstand movement, and they will degrade from sunlight, temperature, and oxidation. Caulks dry up, they shrink, they freeze and crack, they decompose — they fail. When your cladding leaks, neither caulking nor sealants will keep water out of your building.

Figure 1: In this hose test, water penetrated brick veneer in less than a minute (below). The wall behind brick veneer must be designed to drain.

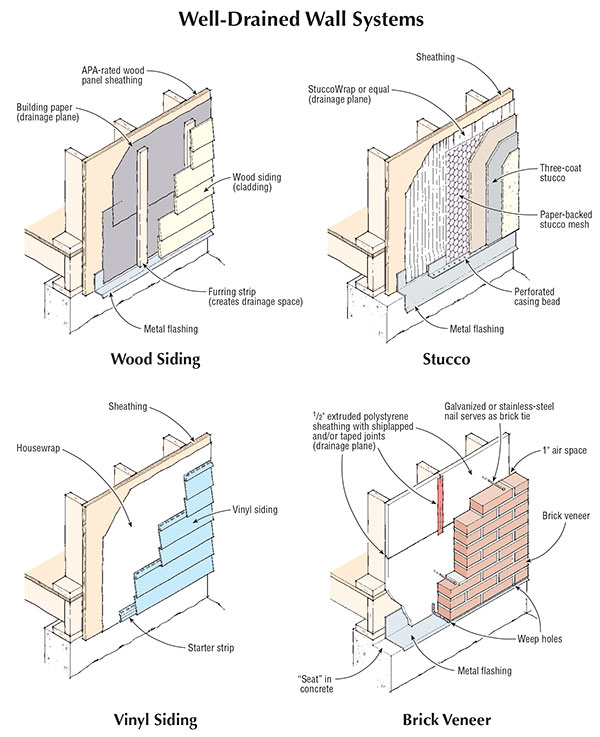

So if all claddings leak, and all sealants and caulks fail, how can we keep buildings dry? By creating a water management system beneath the cladding: a continuous drainage plane with integrated flashings and weep holes, with an air space between the cladding and the drainage plane where water can flow (Figure 2, next page). We overlap everything to direct water down and out, and we let gravity do the work.

Unlike caulks and sealants, gravity is free. Gravity does not wear out, and it does not require maintenance. Gravity is predictable: It always acts downward. In water-managed wall systems, gravity is one thing we can trust.

You can build a water-managed wall system with any cladding and with many different kinds of drainage plane and flashing materials. It will work as long as you follow certain basic principles. Human beings discovered those principles thousands of years ago, but some people still don’t follow them; that’s why people like myself, who investigate building failures, have such wonderful job security.

Figure 2: The key elements in rain control are a drainage plane, a drainage space under the cladding, flashings that integrate with the drainage plane, and weep holes to allow water to escape. These principles can be applied with any cladding system and with many different drainage plane and flashing materials.

Elements of a Rain-Managed Wall

There are four fundamental requirements for water-managed assemblies:

- Drainage plane: some water-repellent material, overlapped to drain downward, and continuous over the whole building exterior. “Continuous” is the key word here. All it means is that you should connect your windows and doors to the drainage plane, as well as your deck, your roof-wall intersections, any service penetrations — everything. Every single flashing must tie into the drainage plane and dump on top of it, not behind it. There are no exceptions: One reverse lap or unflashed penetration can ruin your whole wall.

- Drainage space between the cladding and the drainage plane (the space can be very narrow, but it must be there). The water needs space to move.

- Flashings at every opening, penetration, or intersection, designed to kick water out and down.

- Weep holes: openings to allow water to escape to the outside.

If you have those four elements, you have a water-managed system. If you’re missing any one, or you do any of them wrong, you can expect trouble.

Drainage Planes and Air Spaces

There are many choices of drainage plane material, and there’s a lot of discussion over which is best. The most common drainage planes on houses are still the various building papers — asphalt-saturated felt, plastic housewraps, and coated papers. Housewrap makers like to stress the advantages of their brands, but the difference between one paper and another is really a minor issue. It’s how you use them that counts, and the key factors are the air space and the flashings.

Let’s take an example. Figure 3, page 4, shows a classic drainage plane: tar paper installed shingle fashion behind the cladding. In this case, the cladding is stucco. Do you see the air space? No, because there isn’t one. But there’s supposed to be one, and in the old days there usually was. The reason we often don’t get a drainage space behind stucco today is that tar paper has changed.

Figure 3: Portland cement stucco bonds tightly to modern asphalt felts, denying water the drainage space it needs to flow down and escape the wall. Moisture that penetrates stucco will saturate the paper and destroy its water repellency, wetting the wall structure beneath unless an air space is somehow created.

Decades ago, there was a product called 15-pound felt — asphalt-impregnated rag felt paper that weighed 15pounds per 100 square feet. Today, in its place we have “#15 felt,” which weighs less than 7 pounds per 100 square feet. In place of the old 30-pound felt, we now have #30 felt, which weighs 16.5 or 17 pounds. The papers are lighter and contain less asphalt.

The old heavy felts absorbed water and swelled up when we applied a scratch coat of stucco over them. They were intended to swell. Then as the felt paper dried, it wrinkled, shrank, and debonded from the back of the stucco, creating a thin, convoluted drainage space. If you tear into an old stucco wall, you’ll see the space. But that process doesn’t happen with modern asphalt felt papers — instead, the paper bonds to the stucco and sticks. It gets wet and stays wet, there’s no drainage, and the paper starts to rot. Then your wall is unprotected.

West of the Mississippi, they figured it out. Western stucco applicators use two layers of Type D coated paper under their stucco instead of one layer of asphalt felt, and drainage occurs between the two layers of paper. The stucco might bond to the top layer, but the layer underneath stays free. Some brands of Type D paper even come with pieces of grit stuck on them, which helps to hold the two layers of paper apart.

My point is, any building paper will fail if it bonds to the cladding, and the system can’t drain without an air space. With stucco, we create the air space by using two layers of paper. . .

Download complete document here.